AI in Oil and Gas Industry: Reducing Operational Costs

In today's fast-paced world, the oil and gas industry is undergoing a seismic shift thanks to artificial intelligence (AI). Imagine a world where companies can predict equipment failures before they happen, optimize production processes in real-time, and enhance safety measures—all while significantly cutting costs. This is not just a dream; it's the new reality that AI is creating. By leveraging innovative technologies and data-driven decisions, the oil and gas sector is poised to transform its operational landscape. In this article, we will explore how AI is revolutionizing the industry, leading to smarter operations and substantial financial savings.

AI technologies are being seamlessly integrated into various aspects of the oil and gas industry, from exploration to production. This integration is akin to fitting a high-performance engine into an aging vehicle; it vastly improves efficiency and performance. For instance, AI algorithms can analyze geological data to identify the best drilling locations, reducing the time and costs associated with exploration. Furthermore, AI-driven systems can monitor drilling operations in real-time, allowing for immediate adjustments that enhance productivity.

But the benefits of AI extend beyond exploration. In production, AI helps manage operations by predicting equipment failures and scheduling maintenance proactively. Think of it as having a personal assistant who ensures that everything runs smoothly—no more unexpected breakdowns or costly downtime. By utilizing predictive maintenance, companies can not only save on repair costs but also extend the lifespan of their equipment, leading to even greater savings.

Moreover, the data analytics capabilities of AI provide insights that empower companies to make informed decisions. By analyzing vast amounts of data, AI can identify trends and patterns that human analysts might miss. This ability to leverage data effectively can result in improved operational strategies and significant cost savings. It's like having a crystal ball that reveals the best path forward, enabling companies to navigate the complexities of the oil and gas industry with confidence.

To illustrate the impact of AI on operational costs, consider the following table:

| AI Application | Cost Reduction Impact |

|---|---|

| Predictive Maintenance | Reduces downtime and maintenance costs by up to 30% |

| Data Analytics | Improves decision-making efficiency, leading to 15% savings in operational costs |

| Real-Time Monitoring | Enhances safety and reduces accident-related costs by 20% |

| Supply Chain Optimization | Reduces logistics costs by 25% |

As we delve deeper into the world of AI in the oil and gas industry, we will uncover the various technologies and methodologies that are driving these transformations. From machine learning models that analyze historical data to real-time monitoring systems that respond to operational issues instantly, the potential for cost reduction is immense. It's not just about cutting costs; it's about creating a more efficient, safer, and sustainable industry for the future.

- How does AI improve safety in the oil and gas industry? AI enhances safety by monitoring operations in real-time and predicting potential hazards, allowing for immediate corrective actions.

- What are the main benefits of predictive maintenance? Predictive maintenance reduces unexpected equipment failures, lowers maintenance costs, and extends the lifespan of machinery.

- Can AI help in supply chain management? Absolutely! AI streamlines logistics and inventory management, leading to significant cost savings.

- What future trends can we expect from AI in this industry? Future trends include advancements in machine learning, enhanced data analytics capabilities, and increased automation of operations.

Understanding AI Applications in Oil and Gas

Artificial Intelligence (AI) is not just a buzzword; it's a game changer in the oil and gas industry. Imagine a world where drilling operations are optimized, equipment failures are predicted before they occur, and safety risks are minimized—all thanks to the power of AI. This technology is being integrated into various facets of the oil and gas sector, revolutionizing how companies operate and make decisions.

From exploration to production, AI applications are enhancing operational efficiency. For instance, during the exploration phase, AI algorithms analyze vast amounts of geological data to identify potential drilling sites with higher success rates. This not only saves time but also reduces costs associated with unsuccessful drilling attempts. Moreover, AI can assist in seismic data interpretation, allowing geologists to make more informed decisions.

Once drilling begins, AI continues to play a crucial role. Predictive maintenance is one of the most significant applications, where machine learning models analyze historical data to forecast equipment failures. This proactive approach means that companies can address issues before they escalate, significantly cutting down on downtime and maintenance costs.

Furthermore, AI technologies are also streamlining production processes. For instance, AI-powered systems can optimize drilling parameters in real-time, ensuring that operations are running at peak efficiency. This not only maximizes output but also minimizes waste, leading to substantial cost savings.

In addition to exploration and production, AI is making waves in the supply chain management of oil and gas. By utilizing advanced algorithms, companies can predict demand fluctuations, optimize inventory levels, and enhance logistics operations. This means lower operational costs and a more agile response to market changes.

Overall, the integration of AI in the oil and gas industry is not just about enhancing efficiency; it's about creating a safer, more sustainable future. As companies continue to embrace these technologies, the potential for cost reduction and operational excellence will only grow.

Cost Reduction through Predictive Maintenance

In an industry where every second counts and operational efficiency can make or break a company's bottom line, predictive maintenance emerges as a game-changer. By harnessing the power of artificial intelligence, companies in the oil and gas sector are not just reacting to equipment failures; they are anticipating them. Imagine having a crystal ball that tells you when your machinery is likely to fail. That's precisely what predictive maintenance offers—a proactive approach that helps in minimizing downtime and significantly reducing maintenance costs.

So how does it work? At its core, predictive maintenance leverages data analytics and machine learning algorithms to assess the condition of equipment in real-time. By analyzing historical data and operational parameters, AI can identify patterns that indicate when a piece of equipment is likely to fail. This means that instead of waiting for a machine to break down and disrupt operations, companies can schedule maintenance at optimal times, thus improving efficiency and saving money.

To implement predictive maintenance effectively, companies typically employ a combination of techniques and tools. For instance, IoT sensors can be installed on critical equipment to continuously monitor performance metrics such as temperature, vibration, and pressure. These sensors feed data into an AI system that processes the information and provides actionable insights. The result? A significant reduction in unplanned downtime, which is often one of the most costly aspects of oil and gas operations.

| Benefits of Predictive Maintenance | Impact on Costs |

|---|---|

| Reduced Downtime | Minimizes lost production time and associated costs. |

| Lower Maintenance Costs | Prevents costly emergency repairs and extends equipment lifespan. |

| Improved Safety | Reduces the likelihood of accidents, which can be expensive and damaging. |

Moreover, the financial implications of predictive maintenance are staggering. According to industry studies, companies that implement predictive maintenance strategies can see a reduction in maintenance costs by as much as 30% to 50%. This is not just a minor improvement; it's a transformative shift that can lead to substantial savings over time. With the oil and gas industry facing increasing pressure to reduce costs while maintaining safety and efficiency, predictive maintenance offers a viable solution.

In conclusion, embracing AI-driven predictive maintenance is not merely an option for oil and gas companies—it's becoming a necessity. As the industry continues to evolve, those who invest in these innovative technologies will not only reduce operational costs but also position themselves as leaders in efficiency and safety. The future is bright for companies willing to adopt predictive maintenance, and the potential for cost savings is too significant to ignore.

- What is predictive maintenance? Predictive maintenance is a proactive maintenance strategy that uses AI and data analytics to predict when equipment is likely to fail, allowing for timely maintenance and reduced downtime.

- How does predictive maintenance save costs? By anticipating equipment failures, companies can schedule maintenance more effectively, reducing unplanned downtime and minimizing expensive emergency repairs.

- What technologies are used in predictive maintenance? Technologies include IoT sensors, machine learning algorithms, and advanced data analytics platforms that monitor equipment performance in real-time.

Data Analytics for Enhanced Decision Making

In the fast-paced world of the oil and gas industry, making informed decisions is crucial for maintaining a competitive edge. This is where data analytics comes into play. By harnessing the power of AI-driven analytics, companies can sift through vast amounts of data to uncover valuable insights that drive operational efficiency and cost savings. Imagine having a treasure map that not only shows you where to dig but also tells you the best time to start digging. That's the power of data analytics!

One of the key benefits of utilizing data analytics is the ability to identify patterns and trends that may not be immediately obvious. For instance, by analyzing historical production data, companies can pinpoint the optimal conditions for extraction, leading to increased output and reduced costs. Additionally, predictive analytics can forecast future performance based on past data, allowing companies to plan their strategies more effectively. This proactive approach not only saves money but also enhances overall operational efficiency.

Moreover, data analytics can significantly improve resource allocation. By analyzing consumption patterns and operational metrics, companies can optimize their resource distribution, ensuring that every dollar spent is contributing to the bottom line. For example, if a company realizes that a particular drilling site is underperforming, they can reallocate resources to more productive areas, maximizing their investment. This kind of strategic maneuvering is essential in an industry where margins can be thin.

To illustrate the impact of data analytics on decision-making, consider the following table that highlights the various applications of data analytics in the oil and gas sector:

| Application | Description | Benefits |

|---|---|---|

| Exploration Data Analysis | Analyzing geological data to identify potential drilling sites. | Increased success rates in finding oil and gas reserves. |

| Production Optimization | Using historical data to optimize extraction processes. | Higher production efficiency and lower operational costs. |

| Market Trend Analysis | Examining market data to predict price fluctuations. | Better financial planning and risk management. |

| Supply Chain Analytics | Analyzing supply chain data to enhance logistics. | Reduced costs and improved delivery times. |

In conclusion, the integration of data analytics into decision-making processes within the oil and gas industry is not just a trend; it's a game-changer. Companies that embrace these technologies will find themselves not only cutting costs but also positioning themselves for long-term success. The ability to make data-driven decisions can be the difference between leading the market and playing catch-up. So, why wait? The future is here, and it’s data-driven!

- What is data analytics in the oil and gas industry?

Data analytics involves the use of AI and statistical methods to analyze data from various sources in the oil and gas sector to improve decision-making and operational efficiency.

- How does predictive maintenance work?

Predictive maintenance uses data analytics to predict when equipment is likely to fail, allowing companies to perform maintenance before issues arise, thus reducing downtime and costs.

- What are the benefits of using AI in decision-making?

AI enhances decision-making by providing insights from large datasets, leading to better resource allocation, cost savings, and improved operational strategies.

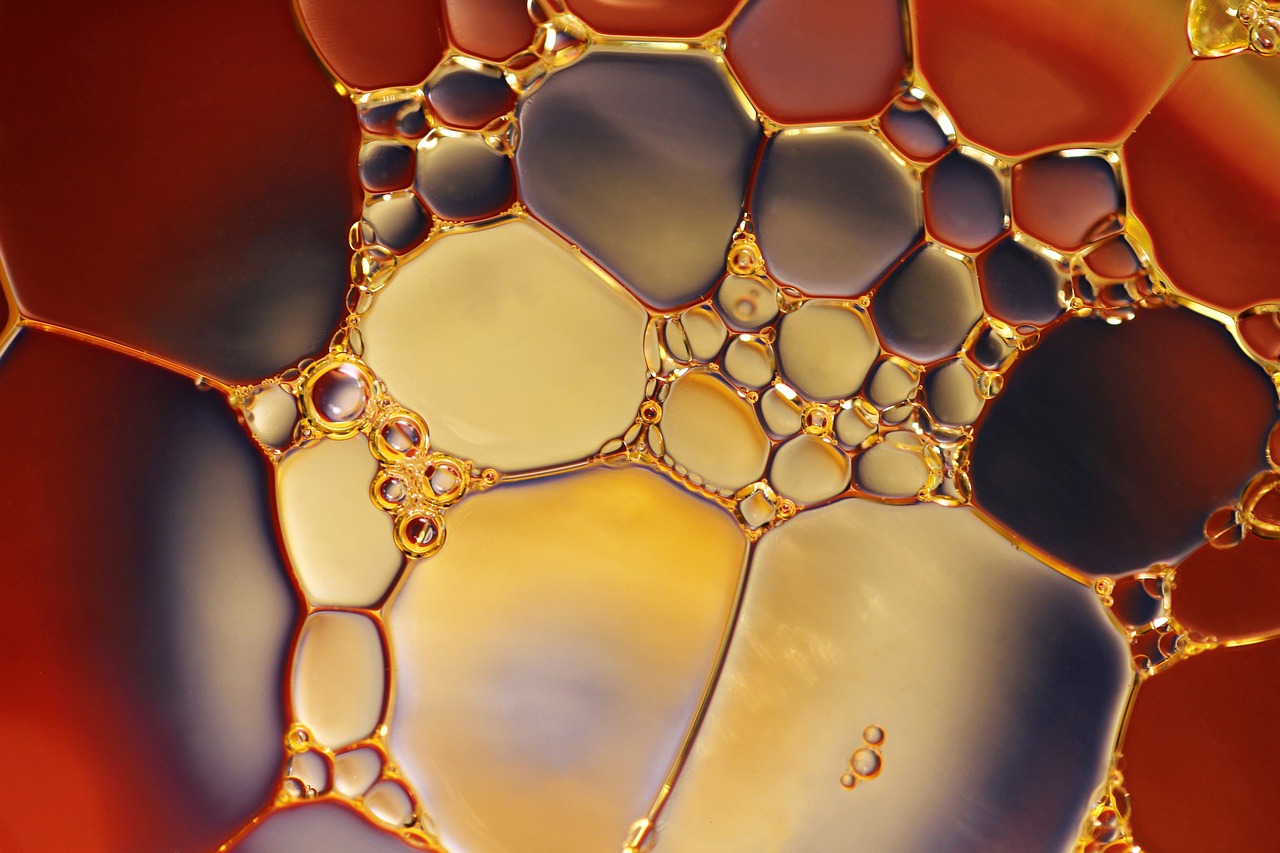

Real-Time Monitoring Systems

In the fast-paced world of the oil and gas industry, powered by artificial intelligence have emerged as game-changers. Imagine a scenario where every piece of equipment is constantly watched over, with data flowing in like a river, ready to be analyzed at a moment's notice. This is not just a dream; it's the reality that AI is bringing to the table. These systems collect vast amounts of data from various sensors installed on drilling rigs, pipelines, and refineries, allowing companies to monitor their operations in real time. By leveraging this technology, businesses can gain insights that were previously unimaginable, leading to quicker decision-making and enhanced operational efficiency.

One of the most significant benefits of these monitoring systems is their ability to detect anomalies before they escalate into serious problems. For instance, if a sensor indicates that a pump is operating outside its normal parameters, the system can alert operators instantly, enabling them to take corrective action. This proactive approach not only prevents costly equipment failures but also minimizes the risk of accidents, which can have dire consequences in this industry. The financial implications are substantial; by reducing the likelihood of unplanned downtime, companies can save millions of dollars.

Furthermore, real-time monitoring systems contribute to safety by ensuring that any hazardous conditions are identified and addressed immediately. For example, if a gas leak is detected, the system can trigger alarms and initiate safety protocols, protecting employees and the environment. This level of vigilance is crucial in an industry where the stakes are high, and the margin for error is slim. The integration of AI into these systems enhances their capabilities, enabling them to learn from historical data and improve their predictive accuracy over time.

To illustrate the impact of real-time monitoring systems, consider the following table that outlines key features and benefits:

| Feature | Benefit |

|---|---|

| 24/7 Monitoring | Continuous oversight of operations, reducing the risk of unnoticed failures. |

| Anomaly Detection | Immediate alerts for irregularities, allowing for swift intervention. |

| Data Analytics | In-depth analysis of operational data to optimize performance and reduce costs. |

| Safety Protocol Activation | Automatic initiation of safety measures in response to detected hazards. |

In conclusion, real-time monitoring systems represent a significant leap forward for the oil and gas industry. By harnessing the power of AI, these systems not only help in reducing operational costs but also play a critical role in enhancing safety. As technology continues to evolve, we can expect these systems to become even more sophisticated, providing even greater insights and efficiencies. The future is bright for those who embrace these innovations, as they stand to gain a competitive edge in an increasingly challenging market.

Machine Learning Models

In the ever-evolving landscape of the oil and gas industry, have emerged as a game-changer, revolutionizing the way companies approach operational efficiency. These sophisticated algorithms analyze vast amounts of historical data, identifying patterns and trends that human analysts might overlook. Imagine having a crystal ball that not only predicts future outcomes but also optimizes processes to save time and money. That's the power of machine learning!

One of the most significant advantages of machine learning in this sector is its ability to enhance predictive analytics. By leveraging historical data, these models can forecast equipment failures and operational bottlenecks before they occur. This proactive approach allows companies to take preventative measures, minimizing downtime and maintenance costs. For instance, if a drilling rig is showing signs of wear and tear based on past performance data, machine learning algorithms can alert operators to schedule maintenance before a catastrophic failure happens.

Moreover, machine learning models are not limited to just predictive maintenance. They can also optimize various operational processes, such as:

- Drilling Optimization: By analyzing geological data, machine learning can help determine the best drilling techniques for specific locations, reducing costs and increasing efficiency.

- Production Forecasting: These models can predict future production rates based on historical data, helping companies manage resources more effectively.

- Energy Consumption Management: Machine learning can analyze energy usage patterns, suggesting ways to reduce consumption and associated costs.

Additionally, machine learning models can continuously learn and adapt over time. This means that as more data becomes available, the algorithms refine their predictions and recommendations, leading to even greater efficiencies. It’s like having a team of experts who never stop learning and improving their strategies!

To illustrate the impact of machine learning in the oil and gas industry, consider the following table that highlights some key performance improvements:

| Application | Impact on Efficiency | Cost Savings |

|---|---|---|

| Predictive Maintenance | Reduced downtime by up to 30% | Up to 25% savings in maintenance costs |

| Drilling Optimization | Increased drilling speed by 15% | Reduced drilling costs by 20% |

| Production Forecasting | Improved accuracy of forecasts by 40% | Enhanced resource allocation, saving 10% on operational costs |

In conclusion, machine learning models are not just a trend; they are a vital component of the future of the oil and gas industry. By harnessing the power of data, these models drive efficiency, reduce costs, and ultimately lead to safer and more sustainable operations. As companies continue to invest in AI technologies, the potential for further innovations in machine learning will only grow, paving the way for a more efficient and cost-effective industry.

Q: How does machine learning improve predictive maintenance?

A: Machine learning analyzes historical data to identify patterns that indicate potential equipment failures, allowing companies to perform maintenance before issues arise.

Q: What are the key benefits of using machine learning in oil and gas?

A: Benefits include reduced downtime, optimized drilling processes, improved production forecasting, and overall cost savings.

Q: Can machine learning adapt to new data?

A: Yes, machine learning models continuously learn and improve their predictions as they are fed more data, making them increasingly effective over time.

AI in Supply Chain Optimization

In the fast-paced world of oil and gas, the supply chain is like the lifeblood of the industry—it keeps everything flowing smoothly. However, managing this complex network can be challenging, often leading to inefficiencies and inflated costs. This is where Artificial Intelligence (AI) steps in, acting as a game-changer. By leveraging AI technologies, companies can streamline their supply chain processes, making them more efficient and cost-effective.

One of the primary ways AI enhances supply chain optimization is through demand forecasting. Traditional forecasting methods often rely on historical data and guesswork, which can lead to overstocking or stockouts. AI, on the other hand, utilizes advanced algorithms and machine learning to analyze vast amounts of data—considering factors like market trends, seasonal changes, and even geopolitical events. This allows for more accurate predictions, ensuring that companies have the right amount of resources at the right time, thereby minimizing waste and reducing costs.

Another significant aspect is inventory management. AI can automate and optimize inventory levels by continuously monitoring stock levels and usage rates. For instance, AI systems can analyze patterns in consumption and automatically reorder supplies when they reach a predetermined threshold. This not only saves time but also reduces the chances of human error, further driving down operational costs.

Moreover, AI enhances logistics management by optimizing routes and delivery schedules. By analyzing real-time data, AI can identify the most efficient paths for transportation, taking into account traffic conditions, weather, and other variables. This results in quicker deliveries and lower fuel costs, which can significantly impact the bottom line. In fact, a recent study showed that companies utilizing AI in their logistics operations could reduce transportation costs by up to 20%.

To illustrate the impact of AI on supply chain optimization, consider the following table:

| AI Application | Benefit | Cost Reduction Potential |

|---|---|---|

| Demand Forecasting | Improved accuracy in predicting needs | Up to 15% |

| Inventory Management | Automated reordering and reduced stockouts | 10-20% |

| Logistics Optimization | Efficient routing and scheduling | 15-25% |

Lastly, AI can also enhance supplier relationship management. By analyzing supplier performance data, companies can identify which suppliers consistently meet their expectations and which do not. This insight allows businesses to make informed decisions about their partnerships, ultimately leading to better negotiations and reduced costs. Think of it as having a personal assistant who not only tracks your suppliers but also provides insights on how to get the best deals!

In conclusion, the integration of AI into supply chain optimization is not just a trend; it’s a necessity for companies looking to thrive in the oil and gas industry. By improving forecasting accuracy, automating inventory management, optimizing logistics, and enhancing supplier relationships, AI is paving the way for significant cost reductions and operational efficiencies. The future is bright for those who embrace these innovative technologies.

- What is AI in supply chain optimization? AI in supply chain optimization refers to the use of artificial intelligence technologies to enhance various aspects of the supply chain, including forecasting, inventory management, logistics, and supplier relationships.

- How can AI reduce costs in the supply chain? AI can reduce costs by improving forecasting accuracy, automating inventory management, optimizing logistics routes, and enhancing supplier performance monitoring.

- What are the benefits of using AI for demand forecasting? The benefits include increased accuracy in predicting product needs, reduced stockouts, and minimized waste, leading to significant cost savings.

Improving Safety with AI Technologies

In the high-stakes world of the oil and gas industry, safety is not just a priority; it’s a necessity. With the integration of artificial intelligence (AI), companies are not only enhancing operational efficiency but also significantly improving safety measures. Imagine a world where potential hazards are identified before they escalate into serious incidents. This is the power of AI technologies in safety management.

One of the most impressive applications of AI in safety is through automated safety monitoring systems. These systems utilize advanced algorithms and real-time data analytics to detect hazards as they occur. For instance, AI can analyze data from sensors placed throughout oil rigs and refineries to identify anomalies that could indicate dangerous conditions. This proactive approach allows for immediate responses, thereby minimizing the risk of accidents. The impact of such systems can be profound, not just in terms of safety but also in reducing the associated costs of accidents and downtime.

Moreover, AI-driven training and simulation tools are revolutionizing how employees prepare for emergency situations. Traditional training methods often rely on theoretical knowledge and infrequent drills, which can leave workers unprepared for real-life scenarios. However, with AI, training can be tailored to simulate actual conditions that employees may face. These simulations can replicate various emergency situations, enabling workers to practice their responses in a safe environment. This hands-on experience is invaluable, as it equips them with the skills and confidence needed to handle crises effectively.

To illustrate the effectiveness of AI in safety management, consider the following table showcasing the benefits:

| AI Technology | Benefits |

|---|---|

| Automated Safety Monitoring |

|

| Training and Simulation Tools |

|

As we look to the future, the potential for AI to further enhance safety in the oil and gas industry is immense. With continuous advancements in machine learning and data analytics, we can expect even more sophisticated systems that not only predict but also prevent accidents before they happen. This evolution will not only protect the workforce but will also safeguard the environment, which is a critical concern in this sector.

In conclusion, the integration of AI technologies in safety protocols is not merely an upgrade; it’s a transformative shift that redefines how the oil and gas industry approaches safety. By leveraging AI for automated monitoring and enhanced training, companies are making significant strides toward a safer working environment. The question remains: how far can AI take us in ensuring the safety of our operations? The possibilities are exciting and full of promise.

Q1: How does AI improve safety in the oil and gas industry?

AI improves safety by enabling real-time hazard detection and providing advanced training simulations for employees, allowing for proactive risk management.

Q2: What are automated safety monitoring systems?

These systems use AI algorithms to analyze data from various sensors to identify potential hazards and facilitate immediate responses to prevent accidents.

Q3: How can training tools powered by AI benefit employees?

AI-driven training tools provide realistic simulations of emergency situations, enhancing employees' preparedness and confidence in handling crises.

Automated Safety Monitoring

In the high-stakes world of the oil and gas industry, the safety of personnel and equipment is paramount. This is where systems powered by artificial intelligence come into play. By leveraging advanced technologies, these systems are revolutionizing how safety is managed on-site. Imagine having a vigilant guardian that never sleeps, constantly scanning for potential hazards and alerting teams before a situation escalates. This is not just a futuristic dream; it’s a reality that is already improving safety standards and reducing operational costs.

Automated safety monitoring systems utilize a combination of real-time data analytics, machine learning algorithms, and sensor technology to detect anomalies and potential risks. For instance, these systems can monitor equipment performance and environmental conditions, identifying issues such as gas leaks, equipment malfunctions, or unsafe pressure levels. Once a risk is detected, the system can automatically alert the relevant personnel, allowing for immediate action to be taken. This proactive approach not only minimizes the risk of accidents but also significantly reduces the costs associated with emergency responses and equipment damage.

Moreover, the integration of AI in safety monitoring enhances the overall efficiency of operations. Traditional safety checks often rely on human observation, which can be prone to error and oversight. In contrast, AI systems provide a level of consistency and accuracy that is unmatched. They can analyze vast amounts of data in real-time, identifying patterns and trends that humans might miss. This capability allows companies to implement preventive measures before incidents occur, thereby protecting both their workforce and their bottom line.

To illustrate the effectiveness of automated safety monitoring, consider the following table that highlights key benefits and features of these systems:

| Feature | Benefit |

|---|---|

| Real-Time Hazard Detection | Immediate alerts to prevent accidents |

| Data-Driven Insights | Informed decision-making for safety protocols |

| Reduced Human Error | Increased accuracy in safety monitoring |

| Continuous Monitoring | 24/7 surveillance of critical areas |

As the oil and gas industry continues to embrace digital transformation, the role of automated safety monitoring systems will only grow. These technologies not only ensure compliance with safety regulations but also foster a culture of safety within organizations. By prioritizing the well-being of their employees, companies can boost morale and productivity, leading to a more sustainable and profitable operation.

In conclusion, automated safety monitoring is a game-changer for the oil and gas sector. It offers a comprehensive solution to manage risks effectively while minimizing costs. By investing in these advanced systems, companies are not just safeguarding their assets; they are also paving the way for a safer and more efficient future in the industry.

- What is automated safety monitoring? - Automated safety monitoring involves the use of AI and sensor technology to continuously monitor safety conditions and detect potential hazards in real-time.

- How does AI improve safety in the oil and gas industry? - AI enhances safety by providing accurate, real-time data analysis, reducing human error, and enabling proactive risk management.

- What are the cost benefits of automated safety monitoring? - By preventing accidents and minimizing downtime, automated safety monitoring significantly reduces operational costs associated with emergency responses and equipment repairs.

- Can automated safety monitoring systems be integrated with existing technologies? - Yes, these systems can often be integrated with existing operational technologies to enhance safety protocols without requiring a complete overhaul.

Training and Simulation Tools

In the ever-evolving landscape of the oil and gas industry, powered by artificial intelligence are becoming essential for preparing employees to handle emergencies and complex operational scenarios. Imagine being able to practice real-life situations without the associated risks—this is precisely what AI-driven simulations offer. By creating realistic environments where employees can hone their skills, these tools not only enhance learning but also significantly reduce the chances of costly mistakes during actual operations.

One of the primary advantages of using AI in training is the ability to customize learning experiences based on individual performance metrics. For instance, AI can analyze how an employee reacts in various scenarios and tailor the training modules accordingly. This personalized approach ensures that each worker receives the training they need to excel, making the workforce more competent and confident in their abilities. It’s like having a personal coach who knows your strengths and weaknesses and helps you improve where it matters most.

Moreover, these tools can simulate a wide range of scenarios, from routine operations to emergency situations such as oil spills or equipment failures. This capability not only prepares employees to respond effectively but also fosters a culture of safety within the organization. By practicing these situations in a controlled environment, workers can develop the necessary skills to act swiftly and decisively, ultimately minimizing operational risks and associated costs.

To illustrate the impact of training and simulation tools, consider the following table that highlights key benefits:

| Benefit | Description |

|---|---|

| Enhanced Skill Development | Employees gain hands-on experience in a risk-free environment, improving their decision-making skills. |

| Cost Reduction | Reducing the number of accidents and operational errors leads to lower costs associated with repairs and downtime. |

| Increased Safety Awareness | Regular training reinforces safety protocols and encourages a proactive approach to risk management. |

Furthermore, the integration of virtual reality (VR) and augmented reality (AR) in training programs is revolutionizing how employees learn. These technologies create immersive experiences that allow workers to interact with their environment in ways that traditional training methods cannot match. Imagine donning a VR headset and being transported to an offshore rig, where you can practice emergency evacuation procedures or equipment handling. Such experiences not only make training more engaging but also significantly enhance retention of information.

In conclusion, AI-driven training and simulation tools are not just a trend; they are a necessity in the oil and gas industry. By investing in these advanced technologies, companies can ensure that their workforce is well-prepared to tackle the challenges of the field, ultimately leading to safer operations and reduced costs. As the industry continues to embrace innovation, the role of AI in training will undoubtedly expand, paving the way for a more skilled and efficient workforce.

- What are AI-driven training tools? These are advanced systems that use artificial intelligence to create realistic training environments for employees in the oil and gas industry.

- How do simulation tools enhance safety? They allow employees to practice emergency scenarios in a controlled environment, improving their preparedness and response times.

- Can AI customize training programs? Yes, AI analyzes individual performance and tailors training modules to address specific strengths and weaknesses.

- What technologies are used in simulation training? Technologies like virtual reality (VR) and augmented reality (AR) are increasingly being integrated to enhance the training experience.

Future Trends of AI in Oil and Gas

The future of AI in the oil and gas industry is not just a fleeting trend; it represents a seismic shift towards smarter, more efficient operations. As we look ahead, several exciting advancements are on the horizon that promise to revolutionize the way companies operate, manage resources, and ensure safety. Imagine a world where predictive analytics not only forecasts equipment failures but also anticipates market fluctuations. This is the potential that AI holds for the industry.

One of the most significant trends is the integration of AI with Internet of Things (IoT) devices. By connecting various sensors and devices across oil fields and refineries, companies can gather real-time data that feeds into AI algorithms. This synergy allows for an unprecedented level of operational insight. For instance, AI can analyze data from drilling operations to optimize drilling parameters, reducing costs and improving safety. The implementation of smart sensors can also facilitate real-time monitoring of environmental conditions, ensuring compliance with regulations while minimizing ecological impact.

Furthermore, the rise of digital twins—virtual replicas of physical assets—will enable companies to simulate different operational scenarios. This technology allows for testing without the risks associated with real-world trials. By leveraging AI, these digital twins can evolve based on real-time data, providing a dynamic tool for optimizing performance and reducing costs. Companies can run simulations to identify the best strategies for resource allocation, maintenance schedules, and emergency response, all of which contribute to significant cost savings.

Another key trend is the increasing reliance on automated decision-making systems. These systems utilize machine learning algorithms to analyze vast amounts of data and make informed decisions faster than any human could. This not only streamlines operations but also enhances safety by minimizing human error. For example, AI can automatically adjust drilling parameters in response to changing geological conditions, preventing potential accidents and costly downtime.

Moreover, the focus on sustainability is pushing the oil and gas sector to adopt AI-driven solutions that promote environmental stewardship. AI can optimize energy consumption in operations, reducing the carbon footprint and aligning with global sustainability goals. Companies are beginning to utilize AI to analyze emissions data and develop strategies for minimizing environmental impact, which is becoming increasingly important in today’s regulatory landscape.

As we explore these trends, it’s essential to discuss the role of collaborative AI systems. These systems allow for enhanced communication and data sharing among different stakeholders in the oil and gas supply chain. By breaking down silos, companies can achieve greater transparency and efficiency. For instance, AI can facilitate real-time communication between suppliers and operators, ensuring that resources are allocated efficiently, which ultimately leads to cost reductions.

In conclusion, the future of AI in the oil and gas industry is bright and full of potential. With advancements in IoT integration, digital twins, automated decision-making, sustainability initiatives, and collaborative systems, the industry is poised for a transformation that will not only enhance operational efficiency but also significantly reduce costs. Companies that embrace these technologies will likely lead the way in this new era of energy production and management.

- What is AI's role in predictive maintenance? AI helps forecast equipment failures, allowing for timely maintenance and reducing downtime.

- How does AI improve safety in the oil and gas sector? AI technologies enable real-time hazard detection and enhance training simulations for emergency preparedness.

- What are digital twins? Digital twins are virtual models of physical assets that allow for simulation and optimization of operations.

- How can AI contribute to sustainability in oil and gas? AI optimizes energy consumption and helps companies develop strategies to minimize their environmental impact.

Frequently Asked Questions

-

How is AI transforming the oil and gas industry?

AI is revolutionizing the oil and gas sector by optimizing operations, enhancing safety, and significantly reducing costs. Through innovative technologies and data-driven decisions, companies can streamline their processes and improve efficiency across various stages, from exploration to production.

-

What are the key applications of AI in this industry?

AI applications in the oil and gas industry include predictive maintenance, data analytics, real-time monitoring systems, and machine learning models. These technologies help in forecasting equipment failures, analyzing historical data for better decision-making, and optimizing supply chain processes, ultimately leading to cost reductions.

-

How does predictive maintenance reduce operational costs?

Predictive maintenance uses AI to anticipate equipment failures before they occur, allowing companies to perform maintenance only when necessary. This approach minimizes downtime and maintenance costs, as it prevents unexpected breakdowns and extends the lifespan of equipment.

-

What role does data analytics play in decision-making?

AI-driven data analytics provide valuable insights that enable companies to make informed decisions. By analyzing large volumes of data, organizations can identify trends, optimize operational strategies, and ultimately achieve significant cost savings.

-

How do real-time monitoring systems enhance safety?

Real-time monitoring systems powered by AI allow for immediate detection and response to operational issues. By continuously assessing conditions and identifying hazards, these systems help to reduce accidents and improve overall safety in the workplace.

-

What are the benefits of machine learning models in oil and gas?

Machine learning models analyze historical data to identify patterns and optimize processes. This leads to improved efficiency, reduced costs, and better resource management, as companies can make more accurate predictions about operations and maintenance needs.

-

How does AI optimize supply chain processes?

AI technologies streamline supply chain operations by enhancing logistics and inventory management. By predicting demand and optimizing resource allocation, companies can reduce costs associated with excess inventory and improve overall supply chain efficiency.

-

In what ways does AI improve safety in the oil and gas industry?

AI enhances safety through automated monitoring systems that detect hazards in real time and AI-driven training tools that prepare employees for emergency situations. These advancements help minimize accidents, reduce risks, and lower associated costs.

-

What future trends can we expect from AI in this industry?

The future of AI in the oil and gas industry promises further advancements, including more sophisticated predictive analytics, enhanced automation, and improved safety technologies. As these innovations develop, companies can expect even greater cost-saving opportunities and operational efficiencies.