How AI is Influencing the Future of Logistics

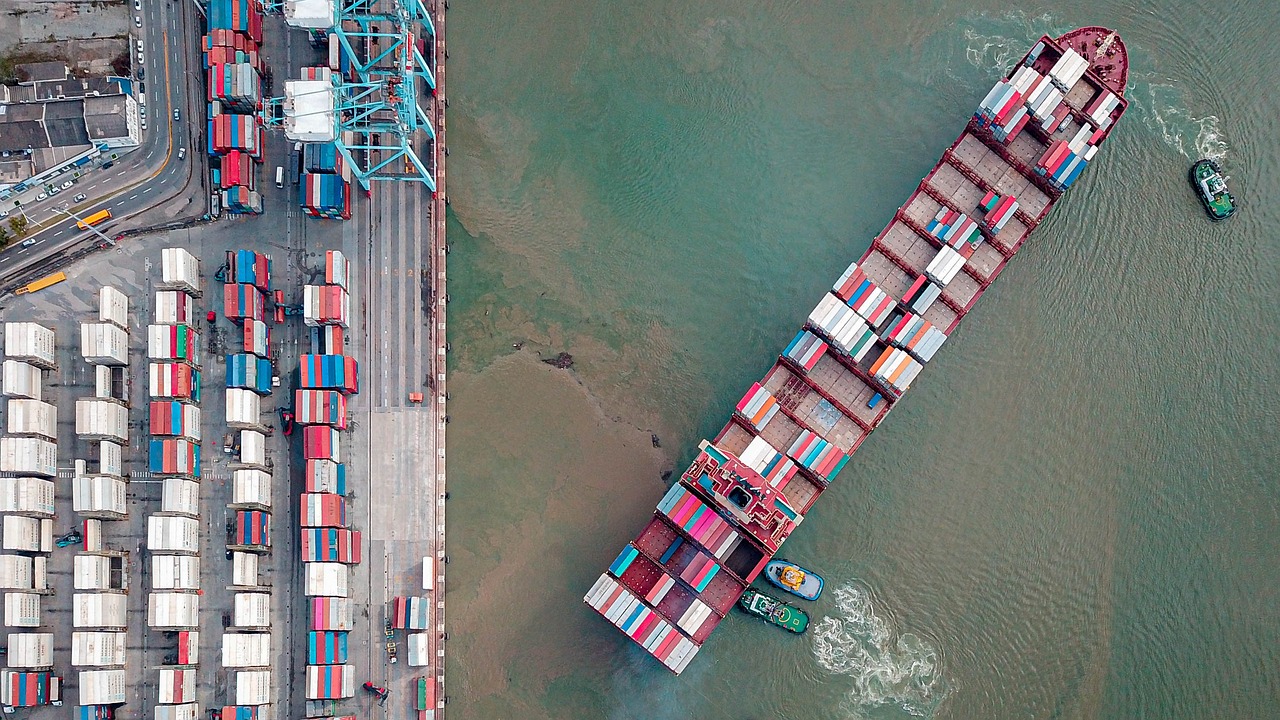

The logistics industry is undergoing a seismic shift, and at the heart of this transformation is artificial intelligence (AI). Imagine a world where deliveries are faster, inventory is managed seamlessly, and customer satisfaction soars. Sounds like a dream, right? Well, this dream is becoming a reality as AI technologies revolutionize how logistics companies operate. From supply chain optimization to enhanced last-mile delivery, AI is not just a buzzword; it’s a game changer. In this article, we’ll explore how AI is reshaping the logistics landscape, making it more efficient and responsive to the needs of businesses and consumers alike.

AI technologies are enhancing supply chain management in ways we never thought possible. By analyzing vast amounts of data, predicting demand, and optimizing inventory levels, AI is paving the way for increased efficiency and reduced costs. Think of it like having an incredibly smart assistant who knows exactly what you need before you even realize it. This proactive approach allows businesses to streamline their operations, minimize waste, and ultimately, boost their bottom line.

One of the most significant contributions of AI to logistics is through predictive analytics. This technology helps logistics companies forecast trends, manage risks, and make data-driven decisions. Imagine being able to anticipate customer demand and adjust your logistics strategies accordingly! With AI, that’s not just a possibility; it’s a reality. By leveraging historical data and market trends, companies can ensure timely deliveries and improved customer satisfaction, leading to a more robust and resilient supply chain.

AI employs various algorithms to analyze historical data and market trends, enabling companies to anticipate customer needs. It’s like having a crystal ball that reveals what customers will want before they even place their orders. This capability allows logistics firms to adjust their strategies, ensuring that they have the right products in the right places at the right times.

At the core of this predictive power are machine learning models. These models process vast datasets, refining forecasting accuracy and allowing logistics firms to respond effectively to changing market conditions. As they learn from new data, these models become increasingly adept at predicting outcomes, making them invaluable assets in the logistics toolbox.

Another exciting aspect of AI in logistics is real-time data analysis. This technology facilitates immediate insights into supply chain operations, enabling quick adjustments and enhancing the overall responsiveness of logistics systems. Imagine being able to react instantly to a delay or disruption in your supply chain—AI makes this possible, ensuring that businesses can maintain operational continuity even in the face of challenges.

AI enhances risk management by identifying potential disruptions in the supply chain. By analyzing data patterns and trends, companies can develop contingency plans that keep operations running smoothly. This proactive approach not only mitigates risks but also builds resilience, allowing businesses to weather unexpected storms with grace.

Automation technologies powered by AI are streamlining warehouse operations, from inventory management to order fulfillment. This shift is akin to upgrading from a bicycle to a high-speed train—everything becomes faster and more efficient. With AI handling repetitive tasks, human resources can focus on more complex activities, enhancing overall productivity and reducing human error.

Robotic process automation (RPA) optimizes repetitive tasks in warehousing, freeing up human resources for more complex activities. This not only boosts efficiency but also improves job satisfaction, as employees can engage in more meaningful work rather than mundane tasks.

AI-driven inventory management systems utilize algorithms to predict stock levels, automate reordering processes, and minimize excess inventory. This leads to significant cost savings and ensures that businesses can meet customer demand without overstocking or understocking.

Last-mile delivery is often the most challenging aspect of logistics, but AI technologies are stepping in to improve this critical phase. Through route optimization, real-time tracking, and enhanced customer communication, AI ensures timely and efficient delivery to end-users. It’s like having a personal delivery assistant who knows the best routes and keeps you informed every step of the way.

AI algorithms analyze traffic patterns and delivery constraints, allowing logistics companies to determine the most efficient routes for their delivery vehicles. This not only saves time but also reduces fuel consumption, contributing to a more sustainable logistics operation.

AI enhances customer experience by providing real-time updates and personalized communication. Customers are no longer left in the dark about their deliveries; they are informed and engaged throughout the process, leading to higher satisfaction rates and repeat business.

The future of logistics will see increased integration of AI technologies, leading to smarter, more connected systems that enhance operational efficiency and customer satisfaction. As we look ahead, it’s clear that AI will continue to shape the logistics landscape in profound ways.

Combining Internet of Things (IoT) devices with AI will enable real-time monitoring and data collection, further optimizing logistics processes and decision-making. This synergy will create a more responsive and agile logistics environment, capable of adapting to changing market demands.

As AI becomes more prevalent in logistics, ethical considerations regarding data privacy, job displacement, and decision-making transparency will need to be addressed by industry leaders. It’s crucial to strike a balance between innovation and ethical responsibility as we embrace this technology.

- How is AI changing the logistics industry? AI enhances efficiency, optimizes supply chains, and improves customer experience.

- What are the benefits of predictive analytics in logistics? Predictive analytics helps forecast demand, manage risks, and make informed decisions.

- What role does automation play in warehousing? Automation streamlines operations, reduces human error, and boosts productivity.

- How does AI improve last-mile delivery? AI optimizes routes, tracks deliveries in real-time, and enhances customer communication.

- What future trends can we expect in AI logistics? Increased integration of AI and IoT technologies, along with a focus on ethical considerations.

AI-Driven Supply Chain Optimization

In today’s fast-paced world, where every second counts, has emerged as a game-changer for businesses across the globe. Imagine a scenario where companies can predict demand with pinpoint accuracy, minimize waste, and streamline their operations—all thanks to the power of artificial intelligence. Sounds like something out of a sci-fi movie, right? But it’s happening now, and it’s revolutionizing the logistics landscape.

AI technologies enhance supply chain management by analyzing massive amounts of data to identify patterns and trends that humans might overlook. By leveraging advanced algorithms, businesses can not only predict demand but also optimize inventory levels, leading to increased efficiency and significant cost reductions. For instance, a company that uses AI for inventory management can reduce excess stock, ensuring that products are available when customers need them without tying up capital in unsold goods.

Let’s break it down a bit further. AI-driven optimization can be categorized into several key areas:

- Data Analysis: AI systems can sift through historical sales data, market trends, and even social media sentiment to provide insights that help businesses make informed decisions.

- Demand Forecasting: By utilizing machine learning models, companies can anticipate customer needs and adjust their logistics strategies accordingly, ensuring they’re always one step ahead.

- Inventory Management: AI algorithms can automate reordering processes and suggest optimal stock levels, reducing the risk of stockouts or overstock situations.

Moreover, the integration of AI in supply chain optimization isn’t just about efficiency; it’s also about agility. In a world where consumer preferences can change overnight, businesses need to be able to pivot quickly. AI enables this by providing real-time insights that allow companies to respond to market changes almost instantaneously. For example, if a sudden spike in demand for a particular product occurs, AI systems can alert managers to adjust their supply chain strategies accordingly.

To illustrate the impact of AI on supply chain optimization, consider the following table:

| Traditional Supply Chain | AI-Optimized Supply Chain |

|---|---|

| Manual data entry and analysis | Automated data analysis with AI algorithms |

| Reactive demand forecasting | Proactive demand forecasting using predictive analytics |

| High inventory costs | Reduced inventory costs through optimized stock levels |

| Slow response to market changes | Rapid response to market changes with real-time insights |

As we move forward, the role of AI in supply chain optimization will only continue to grow. Companies that embrace these technologies will not only improve their operational efficiency but also enhance their competitive edge in the marketplace. In a sense, AI isn’t just a tool; it’s becoming a strategic partner in the logistics industry, helping businesses navigate the complexities of modern supply chains.

So, the next time you receive a package on your doorstep, take a moment to appreciate the intricate dance of logistics that made it possible—all powered by the incredible capabilities of AI.

Predictive Analytics in Logistics

In today's fast-paced world, logistics companies are constantly seeking ways to enhance their operations and deliver exceptional service. Enter predictive analytics, a game-changing technology that harnesses the power of artificial intelligence to forecast trends and optimize decision-making processes. By analyzing vast amounts of historical data, predictive analytics helps logistics firms anticipate customer needs, manage risks, and ensure timely deliveries, all while significantly improving customer satisfaction.

Imagine being able to predict the future of your supply chain with remarkable accuracy. That's what predictive analytics offers. It uses sophisticated algorithms to sift through mountains of data, identifying patterns and trends that might otherwise go unnoticed. This predictive capability allows logistics companies to make informed decisions, reducing inefficiencies and streamlining their operations. For instance, when faced with fluctuating demand, businesses can adjust their logistics strategies in real-time, ensuring they have the right products in the right places at the right times.

One of the primary applications of predictive analytics in logistics is demand forecasting. By leveraging historical sales data, market trends, and external factors such as seasonal changes or economic conditions, AI can predict future demand with impressive accuracy. Here are some techniques commonly used in demand forecasting:

- Time Series Analysis: This method examines historical data points collected over time to identify trends and seasonal patterns.

- Regression Analysis: By analyzing the relationship between different variables, regression helps predict future outcomes based on historical data.

- Machine Learning Models: Advanced algorithms that learn from data patterns, continually improving their accuracy over time.

These techniques enable logistics companies to anticipate customer needs and adjust their inventory levels accordingly. This proactive approach not only minimizes stockouts and overstock situations but also enhances overall operational efficiency.

At the heart of predictive analytics lies machine learning. These models are capable of processing vast datasets, extracting valuable insights that can refine forecasting accuracy. For instance, a logistics firm might use machine learning to analyze customer purchasing behavior, seasonal trends, and even social media sentiment. By doing so, they can better predict demand spikes and adjust their logistics strategies accordingly.

Another crucial aspect of predictive analytics is real-time data analysis. In an industry where every second counts, having immediate insights into supply chain operations is invaluable. Real-time analysis allows logistics companies to monitor their operations continuously, enabling them to make quick adjustments when necessary. For example, if a delivery truck is running late due to traffic, real-time data can help reroute it to ensure timely delivery, thereby enhancing customer satisfaction.

Predictive analytics also plays a vital role in risk management. By identifying potential disruptions in the supply chain—such as supplier failures, natural disasters, or geopolitical issues—logistics companies can develop contingency plans to mitigate risks. This proactive approach not only safeguards operations but also ensures that businesses remain resilient in the face of challenges.

In conclusion, predictive analytics is revolutionizing the logistics industry by enabling companies to make data-driven decisions that enhance efficiency and customer satisfaction. As technology continues to evolve, the integration of predictive analytics will become even more critical for logistics firms looking to stay ahead of the competition.

Q1: What is predictive analytics in logistics?

A1: Predictive analytics in logistics refers to the use of statistical techniques and machine learning algorithms to analyze historical data and forecast future trends, helping companies make informed decisions.

Q2: How can predictive analytics improve customer satisfaction?

A2: By accurately forecasting demand and ensuring timely deliveries, predictive analytics helps logistics companies meet customer expectations, resulting in higher satisfaction levels.

Q3: What role does machine learning play in predictive analytics?

A3: Machine learning models analyze vast datasets to identify patterns and improve forecasting accuracy over time, making them essential for effective predictive analytics.

Q4: Can predictive analytics help with risk management?

A4: Yes, predictive analytics can identify potential disruptions in the supply chain, allowing companies to develop contingency plans and maintain operational continuity.

Demand Forecasting Techniques

Demand forecasting is the backbone of effective logistics management, and with the advent of artificial intelligence, this process has become more sophisticated than ever before. AI employs a variety of algorithms that analyze historical data, market trends, and consumer behavior, enabling logistics companies to predict customer needs with remarkable accuracy. Imagine trying to catch a wave while surfing; if you can read the ocean's patterns and anticipate the swell, you're much more likely to ride it successfully. Similarly, demand forecasting allows businesses to ride the wave of consumer demand, ensuring they have the right products available at the right time.

One of the most effective techniques in demand forecasting is the use of time series analysis. This method looks at historical data over a specific period to identify trends and seasonal patterns. For instance, if a company notices that ice cream sales spike every summer, they can prepare their inventory accordingly. Additionally, AI can integrate external factors such as economic indicators, social media trends, and even weather forecasts to refine these predictions further. The result is a more comprehensive understanding of what customers will want, when they will want it, and how much they will need.

Another powerful technique is the use of machine learning models. These models learn from vast datasets, continuously improving their accuracy as they process more information. For example, a logistics firm might utilize machine learning to analyze previous sales data alongside current market conditions. Over time, the model becomes adept at recognizing patterns that human analysts might miss, leading to more precise demand forecasts. This is akin to having a seasoned navigator on a ship who can read the stars and currents, guiding the vessel safely through turbulent waters.

Moreover, real-time data analysis plays a crucial role in modern demand forecasting. With the ability to analyze data as it comes in, logistics companies can make immediate adjustments to their strategies. For example, if a sudden surge in demand for a particular product is detected, the company can quickly increase production or adjust their supply chain to meet this new demand. This agility is essential in today’s fast-paced market, where consumer preferences can shift in the blink of an eye.

To summarize, the integration of AI in demand forecasting transforms how logistics companies operate. By leveraging techniques such as time series analysis, machine learning models, and real-time data analysis, businesses can enhance their forecasting accuracy, reduce excess inventory, and ultimately improve customer satisfaction. As we move forward, these techniques will continue to evolve, making logistics not just about moving goods, but about understanding and anticipating customer needs in a dynamic marketplace.

- What is demand forecasting? Demand forecasting is the process of predicting future customer demand for a product or service based on historical data and market analysis.

- How does AI improve demand forecasting? AI enhances demand forecasting by analyzing vast amounts of data, identifying patterns, and making predictions that are more accurate than traditional methods.

- What are some common techniques used in demand forecasting? Common techniques include time series analysis, machine learning models, and real-time data analysis.

- Why is demand forecasting important for logistics? Accurate demand forecasting helps logistics companies optimize inventory levels, reduce costs, and improve customer satisfaction by ensuring timely deliveries.

Machine Learning Models

In the ever-evolving landscape of logistics, stand out as a game-changer, revolutionizing how companies process and interpret vast amounts of data. These models are not just algorithms; they are the backbone of intelligent decision-making in logistics. Imagine trying to navigate through a dense forest without a map or GPS. That’s what logistics used to be like—complex and often inefficient. Now, with machine learning, businesses can chart a clear path through the chaos.

At their core, machine learning models analyze historical data to identify patterns and trends that would be nearly impossible for humans to discern. For instance, a logistics company might use machine learning to forecast demand for a specific product. By examining past sales data, seasonal trends, and even social media sentiment, these models can predict future demand with remarkable accuracy. This predictive capability allows companies to adjust their inventory levels proactively, reducing the risk of stockouts or overstock situations.

Moreover, machine learning models continuously learn and adapt. This means that as new data comes in, the models refine their predictions, becoming increasingly accurate over time. Think of it like a personal trainer who adjusts your workout plan based on your progress. In logistics, this adaptability is crucial for staying ahead of market fluctuations and consumer behavior.

One critical aspect of machine learning in logistics is its ability to process real-time data. This is where the magic happens. For example, a logistics company can monitor traffic patterns, weather conditions, and even social media trends to make immediate adjustments to their delivery routes. If a major traffic jam occurs, the machine learning model can quickly analyze alternative routes, ensuring that deliveries remain timely and efficient.

| Benefits of Machine Learning Models in Logistics | Description |

|---|---|

| Increased Accuracy | Machine learning models analyze vast datasets to improve forecasting accuracy. |

| Real-Time Adaptability | Models adjust to new data, enabling quick decision-making in dynamic environments. |

| Cost Efficiency | By optimizing inventory and delivery routes, companies can significantly reduce operational costs. |

| Enhanced Customer Satisfaction | Timely deliveries and accurate inventory management lead to happier customers. |

In conclusion, machine learning models are not just a technological advancement; they are a necessity for logistics companies aiming to thrive in a competitive market. By leveraging these models, businesses can make smarter decisions, enhance operational efficiency, and ultimately provide better service to their customers. The future of logistics is not just about moving goods; it’s about moving them intelligently, and machine learning is the key to unlocking that potential.

- What is machine learning in logistics? Machine learning in logistics refers to the use of algorithms that enable systems to learn from data, identify patterns, and make decisions without human intervention.

- How does machine learning improve forecasting? Machine learning improves forecasting by analyzing historical data and market trends, allowing companies to anticipate customer needs and adjust their logistics strategies accordingly.

- Can machine learning help reduce costs in logistics? Yes, by optimizing inventory levels and delivery routes, machine learning can significantly reduce operational costs.

- Is real-time data analysis important in logistics? Absolutely! Real-time data analysis allows logistics companies to make immediate adjustments based on current conditions, ensuring timely deliveries.

Real-Time Data Analysis

In the fast-paced world of logistics, has emerged as a game changer. Imagine being able to see every single movement of your inventory, every delivery in transit, and every potential hiccup in your supply chain as it happens. This level of visibility not only allows logistics companies to react promptly to issues but also empowers them to make informed decisions that enhance operational efficiency. With real-time data, businesses can optimize their supply chain operations and maintain a seamless flow of goods.

One of the key benefits of real-time data analysis is its ability to provide immediate insights into operational performance. For instance, logistics companies can monitor delivery times, track vehicle locations, and analyze traffic conditions in real-time. This data can then be used to make quick adjustments to routes, ensuring that deliveries are made on time and customers are satisfied. Furthermore, the capability to analyze data as it comes in allows for a more proactive approach to logistics management, rather than a reactive one.

Moreover, real-time data analysis can significantly reduce costs. By identifying inefficiencies and bottlenecks in the supply chain, companies can streamline their operations, thus saving on fuel, labor, and other operational expenses. For example, if a delivery truck is stuck in traffic, real-time data can help reroute it to avoid delays, leading to better fuel efficiency and faster deliveries. The ability to analyze data on-the-fly can also help logistics firms manage their inventory levels more effectively, reducing the risk of overstocking or stockouts.

To illustrate the impact of real-time data analysis, consider the following table that summarizes its advantages:

| Advantage | Description |

|---|---|

| Immediate Insights | Provides real-time visibility into operations, allowing for quick decision-making. |

| Cost Reduction | Identifies inefficiencies and bottlenecks, leading to streamlined operations and lower expenses. |

| Enhanced Customer Satisfaction | Ensures timely deliveries and keeps customers informed about their orders. |

| Proactive Management | Allows companies to anticipate issues and address them before they escalate. |

In essence, real-time data analysis is not just a luxury; it’s a necessity in today’s logistics landscape. The ability to harness data as it flows in enables companies to stay ahead of the competition, adapt to changing market conditions, and ultimately provide a better service to their customers. As logistics continues to evolve, the reliance on real-time data will only increase, making it a cornerstone of successful supply chain management.

- What is real-time data analysis in logistics?

Real-time data analysis in logistics involves monitoring and analyzing data as it is generated, providing immediate insights into supply chain operations. - How does real-time data analysis improve efficiency?

It allows logistics companies to make quick adjustments to routes and operations based on current conditions, reducing delays and optimizing resource use. - Can real-time data analysis help reduce costs?

Yes, by identifying inefficiencies and enabling proactive management, companies can save on operational costs significantly. - Why is real-time data analysis crucial for customer satisfaction?

It ensures timely deliveries and keeps customers informed, which enhances their overall experience and trust in the logistics provider.

Risk Management Strategies

In the fast-paced world of logistics, risk management has become a crucial component of operational success. As supply chains grow more complex and interconnected, the potential for disruptions increases. This is where artificial intelligence (AI) steps in, revolutionizing how companies identify, assess, and mitigate risks. By leveraging advanced algorithms and data analytics, AI can predict potential disruptions before they occur, allowing businesses to be proactive rather than reactive.

One of the key benefits of AI in risk management is its ability to analyze vast amounts of data from various sources. For instance, by examining historical data, weather patterns, and geopolitical events, AI can identify trends that may indicate potential risks. This capability enables logistics companies to develop robust contingency plans, ensuring operational continuity even in the face of unforeseen challenges.

Moreover, AI-driven risk management strategies can be categorized into several critical components:

- Predictive Analytics: By employing machine learning models, companies can forecast potential disruptions with remarkable accuracy. These models analyze historical data and current market conditions to predict risks, allowing businesses to adjust their strategies accordingly.

- Real-Time Monitoring: AI systems can continuously monitor supply chain operations, providing real-time insights into potential disruptions. This immediate feedback loop enables logistics firms to make quick adjustments, minimizing downtime and maintaining service levels.

- Scenario Planning: AI can simulate various risk scenarios, helping companies understand the potential impact of different disruptions. This strategic foresight allows organizations to prepare for the unexpected and allocate resources effectively.

Furthermore, AI enhances collaboration across the supply chain by facilitating communication between partners. When a risk is identified, AI systems can alert all stakeholders, ensuring that everyone is on the same page and can take necessary actions swiftly. This level of transparency not only strengthens relationships but also builds trust among partners, ultimately leading to a more resilient supply chain.

To illustrate the effectiveness of AI in risk management, consider the following table that highlights some common risks in logistics and how AI can mitigate them:

| Common Risks | AI Mitigation Strategies |

|---|---|

| Supply Chain Disruptions | Predictive analytics to forecast disruptions and develop contingency plans. |

| Inventory Shortages | Real-time monitoring of inventory levels to avoid stockouts. |

| Delivery Delays | Route optimization algorithms to ensure timely deliveries. |

| Regulatory Compliance Issues | Automated compliance tracking to ensure adherence to regulations. |

In conclusion, the integration of AI into risk management strategies is not just a trend; it’s a necessity for logistics companies aiming to thrive in today’s dynamic environment. By harnessing the power of AI, businesses can not only anticipate and mitigate risks but also enhance their overall operational efficiency. As we move forward, the role of AI in risk management will continue to evolve, paving the way for smarter, more resilient supply chains.

- What are the main benefits of using AI in risk management?

AI enables predictive analytics, real-time monitoring, and scenario planning, which help companies identify and mitigate risks effectively. - How does AI improve supply chain transparency?

AI facilitates communication between stakeholders, ensuring that everyone is informed about potential risks and can act quickly. - Can AI completely eliminate risks in logistics?

No, while AI significantly enhances risk management, it cannot eliminate all risks. However, it allows companies to be better prepared for uncertainties.

Automation in Warehousing

Automation in warehousing is revolutionizing the way businesses manage their inventory and fulfill orders. Thanks to advancements in artificial intelligence (AI), warehouses are becoming more efficient, organized, and responsive to market demands. Imagine a bustling warehouse where robots and AI systems work hand-in-hand with human employees, creating a seamless operation that minimizes errors and maximizes productivity. This isn’t just a futuristic dream; it’s happening right now!

One of the most significant benefits of automation is the ability to streamline warehouse operations. For instance, AI-driven systems can monitor stock levels in real-time, predict when items need to be restocked, and automate the reordering process. This means that businesses can avoid the pitfalls of overstocking or running out of essential items, ultimately leading to cost savings and improved customer satisfaction.

In addition to inventory management, automation also plays a crucial role in order fulfillment. With the help of robotic process automation (RPA), repetitive tasks such as picking and packing can be handled by machines, allowing human workers to focus on more complex activities that require critical thinking and creativity. This shift not only enhances overall productivity but also reduces the risk of human error, which can be costly in the fast-paced world of logistics.

To illustrate the impact of automation in warehousing, consider the following table that highlights key advantages:

| Advantage | Description |

|---|---|

| Increased Efficiency | Automation speeds up processes, allowing for faster order fulfillment and reduced lead times. |

| Cost Reduction | By minimizing errors and optimizing inventory levels, businesses can significantly cut operational costs. |

| Enhanced Accuracy | Automated systems reduce the likelihood of human error, ensuring that orders are picked and packed correctly. |

| Scalability | Automated systems can easily scale to meet increasing demands without compromising performance. |

Moreover, the integration of AI in warehousing doesn’t just stop at automation; it extends to smart inventory management systems. These systems utilize advanced algorithms to analyze data and predict stock levels, allowing businesses to maintain optimal inventory without the need for constant manual checks. This predictive capability is akin to having a crystal ball for inventory management, enabling companies to stay ahead of the curve.

As we look to the future, the role of automation in warehousing will continue to evolve. With the rise of technologies like Internet of Things (IoT), warehouses will become even smarter, allowing for real-time monitoring and data collection that will further optimize logistics processes. The combination of AI and IoT will create a highly interconnected environment where every aspect of the supply chain is monitored and adjusted in real-time, ensuring that businesses can respond swiftly to any changes in demand or supply.

In summary, automation in warehousing is not just a trend; it’s a fundamental shift in how logistics operates. By embracing these technologies, businesses can enhance their efficiency, reduce costs, and improve customer satisfaction, setting themselves up for success in an increasingly competitive market.

- What are the primary benefits of automation in warehousing?

Automation enhances efficiency, reduces costs, and improves accuracy in inventory management and order fulfillment. - How does AI contribute to smart inventory management?

AI analyzes data to predict stock levels and automate reordering processes, ensuring optimal inventory without manual intervention. - Will automation replace human jobs in warehousing?

While automation may reduce the need for repetitive tasks, it will create opportunities for workers to focus on more complex and strategic roles. - How can businesses prepare for the integration of automation?

Businesses should invest in training their workforce and upgrading their technology infrastructure to effectively implement automated systems.

Robotic Process Automation

In the fast-paced world of logistics, Robotic Process Automation (RPA) is emerging as a game-changer. Imagine a warehouse where repetitive tasks are handled by robots, allowing human workers to focus on more complex and strategic activities. This shift not only enhances productivity but also minimizes the chances of human error, which can be costly in terms of both time and resources.

RPA works by automating routine tasks such as data entry, inventory tracking, and order processing. By implementing RPA, logistics companies can streamline their operations and achieve greater efficiency. For instance, when an order is placed, RPA can automatically update inventory levels and notify the shipping department, speeding up the entire fulfillment process.

Here are some key benefits of RPA in logistics:

- Increased Efficiency: By automating repetitive tasks, RPA allows companies to process orders faster and more accurately.

- Cost Reduction: With fewer errors and faster processing times, businesses can save significantly on operational costs.

- Enhanced Employee Satisfaction: Employees can focus on more engaging tasks, leading to higher job satisfaction and retention rates.

Moreover, RPA can be integrated with other technologies such as Artificial Intelligence (AI) and Machine Learning (ML) to create a more holistic approach to logistics management. For example, while RPA could handle the processing of orders, AI could analyze customer data to predict future demand, ensuring that the right products are always in stock.

As we look to the future, the role of RPA in logistics is expected to grow. Companies that embrace this technology will not only gain a competitive edge but also position themselves as leaders in an increasingly automated industry. The integration of RPA with advanced technologies will pave the way for smarter, more efficient logistics operations, ultimately benefiting both businesses and their customers.

- What is Robotic Process Automation?

Robotic Process Automation (RPA) is a technology that automates repetitive tasks typically performed by humans, enhancing efficiency and accuracy in various processes. - How does RPA improve logistics operations?

RPA streamlines operations by automating tasks such as data entry, inventory management, and order processing, leading to faster and more accurate workflows. - Can RPA work alongside other technologies?

Yes, RPA can be integrated with AI and ML to create a more comprehensive logistics management system that predicts demand and optimizes supply chains. - What are the long-term benefits of implementing RPA?

Long-term benefits include increased operational efficiency, reduced costs, improved employee satisfaction, and enhanced customer experiences.

Smart Inventory Management

In today's fast-paced logistics environment, is not just a luxury—it's a necessity. With the rising demand for efficiency and accuracy, AI-driven systems are stepping in to revolutionize how businesses manage their stock. Imagine a world where your inventory is always in sync with customer demand, where overstock and stockouts are relics of the past. Sounds like a dream, right? Well, thanks to AI, this dream is becoming a reality.

At the heart of smart inventory management is the ability to predict stock levels accurately. By utilizing advanced algorithms, AI can analyze historical sales data, seasonal trends, and even external factors like market shifts or economic changes. This predictive capability allows businesses to automate their reordering processes, ensuring that they always have the right amount of stock on hand without tying up too much capital in excess inventory.

Furthermore, AI-driven inventory systems can significantly reduce human error. Traditional inventory management often involves manual counts and estimations, which can lead to discrepancies and inefficiencies. AI takes this burden off human shoulders by continuously monitoring stock levels and automatically adjusting inventory records in real-time. This not only enhances accuracy but also frees up employees to focus on more complex tasks that require human intervention.

To illustrate the impact of smart inventory management, consider the following table that compares traditional inventory practices with AI-driven approaches:

| Aspect | Traditional Inventory Management | AI-Driven Inventory Management |

|---|---|---|

| Forecasting Accuracy | Low, based on historical data and manual input | High, utilizing real-time data and predictive analytics |

| Human Error | High, due to manual processes | Minimal, with automated tracking and updates |

| Response Time | Slower, reliant on manual checks | Instantaneous, with real-time alerts and adjustments |

| Cost Efficiency | Higher costs due to overstock and stockouts | Lower costs through optimized inventory levels |

Ultimately, the implementation of smart inventory management systems powered by AI not only leads to better operational efficiency but also enhances customer satisfaction. When businesses can fulfill orders promptly and accurately, customers are happier, leading to repeat business and positive reviews. And let's face it; in the world of logistics, a happy customer is the best advertisement.

As we look to the future, the integration of AI in inventory management will continue to evolve. Companies that embrace these technologies will not only stay ahead of the competition but will also set new standards in customer service and operational excellence. So, if you're still relying on outdated inventory practices, it might be time to consider making the switch to AI-driven solutions.

- What is smart inventory management? Smart inventory management refers to the use of advanced technologies, particularly AI, to optimize the tracking, ordering, and storage of inventory.

- How does AI improve inventory management? AI improves inventory management by analyzing data to predict demand, automating reordering processes, and minimizing human error.

- Can small businesses benefit from AI in inventory management? Absolutely! AI solutions are scalable and can provide significant benefits to businesses of all sizes, including small enterprises.

- What are the key features of AI-driven inventory management systems? Key features include real-time tracking, predictive analytics, automated reordering, and integration with other supply chain processes.

Enhanced Last-Mile Delivery

In the world of logistics, the last-mile delivery is often seen as the make-or-break moment for customer satisfaction. This is the final stretch where packages travel from distribution centers to the customer’s doorstep. With the rise of e-commerce and consumer expectations skyrocketing, enhancing this segment has become a top priority. Enter artificial intelligence (AI), which is revolutionizing last-mile delivery by making it smarter, faster, and more efficient. Imagine a delivery system that not only knows the best routes but can also adapt to real-time changes in traffic and weather conditions. Sounds like something out of a sci-fi movie, right? Well, it’s happening now!

One of the most significant contributions of AI to last-mile delivery is route optimization. AI algorithms can analyze vast amounts of data, including traffic patterns, delivery constraints, and even historical delivery times. This allows logistics companies to determine the most efficient routes for their delivery vehicles. For instance, if a delivery truck is stuck in traffic, the AI can reroute it to avoid delays, ensuring that packages arrive on time. This not only enhances efficiency but also reduces fuel consumption and operational costs.

Moreover, AI-driven systems provide real-time tracking for both companies and customers. Imagine waiting for a package and being able to see exactly where it is on a map, much like tracking your favorite pizza delivery. This transparency builds trust and keeps customers informed throughout the delivery process. As a result, companies can enhance their customer experience significantly. According to a recent survey, over 70% of customers prefer receiving real-time updates about their deliveries. This means that businesses who leverage AI for last-mile delivery not only improve efficiency but also boost customer satisfaction.

Additionally, AI plays a crucial role in customer communication. By utilizing chatbots and automated messaging systems, logistics companies can engage with customers proactively. If there’s a delay or an issue with the delivery, AI can instantly notify the customer, providing updates and alternative solutions. This level of communication ensures that customers feel valued and informed, which is vital in today’s competitive market.

However, the benefits of AI in last-mile delivery don’t stop there. As we look to the future, we can expect even more innovations such as autonomous delivery vehicles and drone deliveries. These technologies promise to eliminate human error, reduce delivery times, and further enhance efficiency. Just think about it: a drone delivering your package within minutes of placing an order. It’s not just a dream anymore; it’s becoming a reality!

In conclusion, the integration of AI in last-mile delivery is transforming the logistics landscape. With route optimization, real-time tracking, and improved customer communication, businesses can achieve greater efficiency and customer satisfaction. As technology continues to evolve, we can only anticipate even more exciting advancements in this space, making last-mile delivery not just a challenge but an opportunity for innovation.

- What is last-mile delivery? Last-mile delivery refers to the final step of the delivery process, where goods are transported from a distribution center to the end customer.

- How does AI improve last-mile delivery? AI improves last-mile delivery through route optimization, real-time tracking, and enhanced customer communication, leading to increased efficiency and customer satisfaction.

- What are the future trends in last-mile delivery? Future trends include the use of autonomous vehicles and drones, which promise to further streamline the delivery process.

- Why is real-time tracking important? Real-time tracking is crucial as it keeps customers informed about their delivery status, enhancing trust and satisfaction.

Route Optimization Algorithms

Route optimization algorithms are the unsung heroes of modern logistics, working tirelessly behind the scenes to ensure that deliveries are made as efficiently as possible. Imagine you're trying to deliver packages to multiple locations in a bustling city. Without a proper plan, you might find yourself stuck in traffic, wasting time, fuel, and resources. This is where route optimization comes into play, utilizing advanced algorithms to determine the best paths for delivery vehicles.

These algorithms analyze a plethora of factors, including traffic patterns, weather conditions, and even historical delivery data, to create the most efficient routes. For instance, if a delivery truck usually encounters heavy traffic on a specific road during rush hour, the algorithm will suggest an alternative route, saving time and reducing fuel consumption. It's like having a personal GPS that not only finds the fastest way but also adapts to real-time conditions, ensuring that logistics companies can meet tight delivery windows.

One of the key technologies behind these algorithms is machine learning. By continually learning from new data, these systems can improve their recommendations over time. For example, if a certain route consistently leads to delays, the algorithm will recognize this pattern and adjust future route suggestions accordingly. This adaptability is crucial in a world where delivery expectations are higher than ever.

Moreover, the integration of real-time data adds another layer of sophistication to route optimization. With the help of GPS and IoT devices, logistics companies can monitor their vehicles in real-time, allowing them to make on-the-fly adjustments. If a detour becomes necessary due to an unexpected road closure or accident, the algorithm can quickly calculate a new route, ensuring that deliveries stay on schedule. This level of responsiveness is vital in maintaining customer satisfaction, as timely delivery is often a key factor in a customer's perception of service quality.

To illustrate the effectiveness of route optimization algorithms, consider the following table that compares traditional delivery methods with those utilizing advanced algorithms:

| Delivery Method | Time Efficiency | Fuel Consumption | Customer Satisfaction |

|---|---|---|---|

| Traditional Methods | Low | High | Moderate |

| Optimized Routes | High | Low | High |

As we look to the future, the role of route optimization algorithms will only grow. With the rise of e-commerce and the increasing demand for rapid delivery, logistics companies must leverage these technologies to stay competitive. The ability to deliver packages quickly and efficiently is no longer just a nice-to-have; it’s a necessity in today’s fast-paced market.

In conclusion, route optimization algorithms are revolutionizing the logistics industry by enhancing efficiency, reducing costs, and improving customer satisfaction. As technology continues to advance, we can expect even more sophisticated solutions that will further streamline delivery processes and transform the way goods are transported.

- What are route optimization algorithms?

Route optimization algorithms are advanced mathematical models used to determine the most efficient paths for delivery vehicles, taking into account various factors like traffic, weather, and historical data.

- How do these algorithms improve delivery times?

By analyzing real-time data and learning from past delivery experiences, these algorithms can suggest the quickest routes, helping drivers avoid delays and reach their destinations faster.

- Can route optimization algorithms adapt to changing conditions?

Yes! These algorithms are designed to be dynamic, allowing them to make real-time adjustments based on current traffic conditions or unforeseen events, ensuring timely deliveries.

Customer Experience Improvements

In today's fast-paced world, where instant gratification is the norm, customer experience has become a critical factor in the logistics industry. With the integration of artificial intelligence, logistics companies are not just moving products; they are enhancing the entire delivery experience. Imagine being able to track your package in real-time, receiving updates at every stage of its journey, and knowing exactly when it will arrive at your doorstep. This is the new reality that AI is creating for customers.

AI technologies enable logistics companies to provide real-time updates on delivery statuses, which significantly reduces customer anxiety. Gone are the days of waiting for vague delivery windows. Now, customers can receive notifications that inform them of their package's location, estimated delivery time, and any potential delays. This transparency builds trust and keeps customers engaged throughout the process.

Moreover, AI-driven chatbots and virtual assistants are revolutionizing customer service in logistics. These intelligent systems can handle inquiries 24/7, providing customers with immediate answers to their questions. Whether it's tracking a shipment or resolving an issue, AI chatbots can deliver personalized responses based on customer history and preferences. This level of personalization not only enhances the customer experience but also frees up human agents to tackle more complex issues, further improving service efficiency.

Another fascinating aspect of AI in logistics is its ability to analyze customer feedback and behavior. By leveraging data analytics, companies can identify patterns and trends in customer preferences. For instance, if a significant number of customers express dissatisfaction with delivery times, logistics firms can adjust their strategies accordingly. This proactive approach to customer feedback ensures that companies are not only reacting to issues but are also anticipating customer needs.

Furthermore, AI can facilitate a more tailored delivery experience. Imagine a scenario where the system learns your preferred delivery times or locations. AI can optimize routes based on these preferences, ensuring that packages arrive at the most convenient times for the customer. This level of customization creates a more satisfying experience, making customers feel valued and understood.

In summary, the integration of AI in logistics is not just about improving operational efficiency; it's fundamentally about enhancing the customer experience. By providing real-time updates, personalized interactions, and tailored delivery options, AI is transforming logistics into a customer-centric industry. As we move forward, the focus on customer experience will only intensify, making AI an indispensable tool for logistics companies striving to meet and exceed customer expectations.

- How does AI improve customer experience in logistics? AI enhances customer experience by providing real-time tracking updates, personalized communication through chatbots, and tailored delivery options.

- What role do chatbots play in logistics? Chatbots handle customer inquiries 24/7, offering immediate responses and freeing human agents for more complex issues.

- Can AI predict customer preferences? Yes, AI analyzes customer feedback and behavior to identify patterns, allowing logistics companies to anticipate customer needs and improve service.

Future Trends in AI Logistics

The logistics industry is on the brink of a major transformation, largely driven by the rapid advancements in artificial intelligence (AI). As we look to the future, it’s clear that AI will play a pivotal role in reshaping logistics operations, enhancing efficiency, and improving customer experiences. One of the most exciting trends is the increased integration of AI technologies with other emerging technologies, such as the Internet of Things (IoT). This combination will allow for real-time monitoring and data collection, enabling logistics companies to make faster and more informed decisions.

Imagine a world where every shipment is tracked in real-time, and data is analyzed instantly to optimize routes and schedules. This is not just a dream; it’s becoming a reality. With IoT devices collecting data from various points in the supply chain, AI can process this information to enhance operational efficiency. For instance, AI algorithms can predict potential disruptions by analyzing traffic patterns, weather conditions, and even social media trends. This proactive approach to logistics will significantly reduce delays and improve service levels.

Moreover, as AI technologies evolve, we can expect to see more sophisticated predictive analytics tools that will further refine demand forecasting. By harnessing vast amounts of historical data, these tools will help logistics companies anticipate customer needs and adjust their strategies accordingly. This not only leads to better inventory management but also enhances customer satisfaction by ensuring that products are available when and where they are needed.

However, with great power comes great responsibility. As AI becomes more prevalent in logistics, there are important ethical considerations that must be addressed. Issues such as data privacy, job displacement, and decision-making transparency will require careful thought and regulation. Industry leaders must navigate these challenges to ensure that the benefits of AI are realized without compromising ethical standards.

In summary, the future of AI in logistics is incredibly promising. With the integration of IoT devices, enhanced predictive analytics, and a focus on ethical practices, logistics companies will be better equipped to meet the demands of an increasingly dynamic market. As we move forward, it will be fascinating to see how these trends unfold and shape the logistics landscape.

- What is the role of AI in logistics? AI enhances logistics operations by improving efficiency, optimizing supply chain management, and providing real-time data analysis.

- How does IoT integrate with AI in logistics? IoT devices collect data that AI algorithms analyze to optimize logistics processes, such as route planning and inventory management.

- What are the ethical considerations of using AI in logistics? Ethical considerations include data privacy, job displacement, and the need for transparency in AI decision-making.

- What future trends can we expect in AI logistics? Expect increased integration of AI with IoT, advanced predictive analytics, and a stronger focus on ethical practices in the industry.

Integration of IoT and AI

The integration of Internet of Things (IoT) and Artificial Intelligence (AI) is revolutionizing the logistics industry, creating a synergy that enhances operational efficiency and decision-making processes. Imagine a world where every package, vehicle, and warehouse is interconnected, sharing real-time data that can be analyzed and acted upon almost instantaneously. This is not just a dream; it's the reality that IoT and AI are building together. By embedding sensors in delivery trucks and warehouses, companies can gather a wealth of data on everything from temperature and humidity to vehicle location and speed. This data is then processed by AI algorithms, enabling logistics companies to make smarter, data-driven decisions.

For instance, consider a scenario where a shipment of perishable goods is on its way to a grocery store. IoT sensors can monitor the temperature of the cargo in real-time. If the temperature rises beyond a certain threshold, the AI system can automatically alert the driver and suggest the fastest route to the nearest cooling facility. This not only prevents spoilage but also ensures that the delivery remains on schedule, ultimately leading to enhanced customer satisfaction.

Moreover, the integration of IoT and AI facilitates predictive maintenance of logistics assets. By continuously monitoring the performance of vehicles and equipment, AI can predict potential failures before they occur. This proactive approach minimizes downtime and reduces repair costs, allowing companies to maintain smooth operations. The benefits are clear:

- Increased Visibility: Real-time data provides complete visibility into the supply chain.

- Improved Efficiency: Automated processes reduce human error and streamline operations.

- Enhanced Customer Experience: Timely updates and accurate deliveries keep customers informed and satisfied.

As we look to the future, the combination of IoT and AI will continue to evolve, leading to more sophisticated logistics solutions. Companies that harness this technology will not only gain a competitive edge but will also be better equipped to adapt to changing market demands. The logistics landscape is becoming smarter, and those who embrace this change will thrive in the new era of supply chain management.

- What is the role of IoT in logistics? IoT devices collect real-time data on inventory, shipments, and equipment, enhancing visibility and efficiency in logistics operations.

- How does AI improve decision-making in logistics? AI analyzes vast amounts of data to provide insights and predictions that help logistics companies make informed decisions quickly.

- Can IoT and AI reduce costs in logistics? Yes, by optimizing routes, improving inventory management, and reducing downtime, the integration of IoT and AI can lead to significant cost savings.

Ethical Considerations in AI Logistics

As artificial intelligence (AI) continues to revolutionize the logistics industry, it's crucial to address the ethical considerations that accompany this technological advancement. With great power comes great responsibility, and the integration of AI in logistics is no exception. One of the primary concerns revolves around data privacy. Logistics companies collect vast amounts of data, not only about their operations but also about their customers. Safeguarding this sensitive information is paramount, as breaches can lead to significant repercussions, both legally and in terms of customer trust.

Another pressing issue is job displacement. Automation and AI-driven technologies, while improving efficiency, can also render certain jobs obsolete. This raises questions about the future workforce in logistics. Will there be enough new roles created to replace those lost? Industry leaders must consider how to retrain and reskill employees to adapt to this evolving landscape. It's essential to foster a balance where technology complements human labor rather than completely replacing it.

Moreover, the transparency of decision-making processes in AI systems is a topic that cannot be overlooked. AI algorithms often operate as a "black box," making it difficult to understand how decisions are made. This lack of transparency can lead to biases in decision-making, particularly if the algorithms are trained on flawed data. Companies must ensure that their AI systems are designed to be fair and accountable, providing clear insights into how decisions are derived.

To navigate these ethical considerations, logistics companies should implement a framework that emphasizes ethical AI practices. This framework could include:

- Regular audits of AI systems to ensure compliance with ethical standards.

- Employee training programs focused on the ethical use of AI and data privacy.

- Engagement with stakeholders to discuss and address ethical concerns openly.

Ultimately, as logistics companies embrace AI, they must do so with a commitment to ethical practices. By prioritizing data privacy, addressing job displacement, and ensuring transparency, the industry can harness the benefits of AI while maintaining public trust and social responsibility.

1. What are the main ethical concerns regarding AI in logistics?

The primary concerns include data privacy, job displacement, and the transparency of decision-making processes within AI systems.

2. How can logistics companies address data privacy issues?

Logistics companies can implement robust data protection measures, conduct regular audits, and ensure compliance with relevant regulations to safeguard customer information.

3. Will AI lead to job losses in the logistics sector?

While AI may automate certain tasks, it can also create new roles that require different skill sets. Companies should focus on retraining and reskilling their workforce to adapt to these changes.

4. What steps can be taken to ensure transparency in AI decision-making?

Companies can develop AI systems that provide insights into their decision-making processes and conduct audits to identify and mitigate biases in the algorithms.

Frequently Asked Questions

- What role does AI play in supply chain optimization?

AI plays a pivotal role in supply chain optimization by analyzing vast amounts of data to predict demand, streamline inventory management, and enhance overall efficiency. It helps businesses reduce costs and improve service levels by ensuring that the right products are available at the right time.

- How does predictive analytics improve logistics?

Predictive analytics enhances logistics by allowing companies to forecast trends and manage risks effectively. By leveraging historical data and advanced algorithms, logistics firms can make informed decisions that lead to timely deliveries and improved customer satisfaction.

- What are some demand forecasting techniques used in logistics?

Demand forecasting techniques in logistics include time series analysis, machine learning models, and market trend evaluation. These techniques enable companies to anticipate customer needs and adjust their logistics strategies accordingly, ensuring they meet demand without overstocking.

- How does automation impact warehousing?

Automation significantly impacts warehousing by streamlining operations such as inventory management and order fulfillment. Technologies like robotic process automation (RPA) reduce human error and improve efficiency, allowing staff to focus on more complex tasks.

- What improvements does AI bring to last-mile delivery?

AI improves last-mile delivery through route optimization and real-time tracking. By analyzing traffic patterns and delivery constraints, AI ensures that logistics companies can deliver packages efficiently and on time, enhancing the overall customer experience.

- What future trends can we expect in AI logistics?

Future trends in AI logistics include greater integration of IoT devices with AI technologies, leading to enhanced real-time monitoring and data collection. Additionally, there will be a focus on addressing ethical considerations such as data privacy and job displacement as AI becomes more prevalent.

- How can companies manage the ethical considerations of AI in logistics?

Companies can manage ethical considerations in AI logistics by establishing transparent data usage policies, prioritizing employee retraining, and engaging in open dialogues about the implications of AI. This proactive approach helps ensure that the benefits of AI are realized while minimizing potential drawbacks.