3D Printing in the Medical Field: Opportunities and Challenges

In recent years, the emergence of 3D printing technology has sparked a revolution in the medical field, offering unprecedented opportunities to enhance patient care and streamline healthcare processes. Imagine a world where prosthetics can be tailored to fit the unique anatomy of each patient, or where complex surgical procedures can be practiced on accurate, patient-specific models before the actual operation. This is not just a futuristic dream; it is becoming a reality thanks to 3D printing. However, while the benefits are immense, there are also significant challenges that need to be addressed for this technology to reach its full potential in healthcare.

3D printing, or additive manufacturing, allows for the creation of three-dimensional objects from digital files. In the medical field, this technology is being utilized in various applications, including the production of customized prosthetics, the development of organ models for surgical planning, and even the potential for bioprinting tissues and organs. The ability to produce tailored medical solutions can lead to better patient outcomes, as treatments are more aligned with individual needs. For instance, surgeons can create accurate anatomical models that reflect the specific conditions of their patients, thereby improving the precision of surgical interventions.

The advantages of integrating 3D printing in healthcare are numerous and transformative. One of the most significant benefits is the ability to achieve customization. Unlike traditional manufacturing processes, which often produce generic solutions, 3D printing allows for the creation of personalized medical devices that cater to the specific requirements of each patient. This level of customization not only enhances comfort but also improves functionality. For instance, a patient receiving a prosthetic limb can have it designed to fit their unique body shape and lifestyle, leading to a more natural and effective use.

One of the standout applications of 3D printing in medicine is in the creation of customized prosthetics and implants. By using advanced imaging techniques, healthcare professionals can obtain detailed scans of a patient's anatomy, which can then be used to design prosthetics that fit perfectly. This process not only improves the comfort of the prosthetic but also enhances the patient's ability to perform daily activities. For example, a patient with a limb amputation can have a prosthetic that mimics the natural movement of their body, leading to a more active and fulfilling life.

Numerous case studies illustrate the profound impact of 3D-printed prosthetics on patient quality of life. For instance, a young boy who lost his arm in an accident received a 3D-printed prosthetic that was not only functional but also colorful and appealing to him. This customization helped him regain confidence and reintegrate into social activities. Similarly, a patient who underwent a hip replacement surgery benefited from a 3D-printed implant that was tailored to their specific anatomy, resulting in quicker recovery times and reduced post-operative complications.

As technology continues to evolve, the future of customization in 3D printing looks promising. Innovations such as bioprinting, where living cells are printed to create tissues and organs, are on the horizon. Researchers are also exploring the use of advanced materials that can mimic the properties of human tissues, paving the way for even more personalized medical solutions. The potential for creating organs on demand could revolutionize transplantation, significantly reducing waiting times and the risk of rejection.

Another significant benefit of 3D printing is its application in surgical planning and simulation. Surgeons can create accurate models of a patient's anatomy, allowing them to rehearse complex procedures before entering the operating room. This practice not only boosts the surgeon's confidence but also minimizes the risk of errors during surgery. Imagine a pilot practicing on a flight simulator before taking to the skies; this is akin to how surgeons can prepare for intricate operations using 3D-printed models.

Despite the exciting opportunities that 3D printing presents, there are several challenges that hinder its widespread adoption in the medical field. One of the primary concerns is the regulatory landscape. The FDA and other regulatory bodies are still catching up with the rapid advancements in 3D printing technology, leading to uncertainties regarding compliance and safety standards. Additionally, the need for standardization in production processes is critical to ensure that 3D-printed medical devices meet the necessary quality and safety requirements.

The regulatory framework surrounding 3D printing in medicine is complex and evolving. As healthcare providers and manufacturers navigate this landscape, they must adhere to stringent guidelines set forth by regulatory agencies. This can be daunting, especially for smaller companies looking to innovate. The lack of clear regulations can lead to hesitance in adopting new technologies, ultimately slowing down the progress that could benefit patients.

Another challenge lies in the material limitations of current 3D printing technologies. While there are several biocompatible materials available, researchers are actively working to develop new materials that are not only safe for human use but also durable and functional. The ongoing innovation in this area is crucial, as the success of 3D-printed medical devices largely depends on the materials used in their production.

Looking ahead, the future of 3D printing in healthcare appears bright. As technology advances, we can expect to see even more revolutionary applications that will change the way we approach medical treatment. From bioprinting organs to creating advanced surgical tools, the possibilities are endless. The integration of artificial intelligence and machine learning with 3D printing could further enhance customization and efficiency, leading to better patient outcomes and streamlined healthcare processes.

- What is 3D printing in healthcare? - 3D printing in healthcare refers to the use of additive manufacturing technology to create customized medical devices, prosthetics, and even biological tissues.

- How does 3D printing benefit patients? - It allows for personalized solutions that improve comfort, functionality, and overall patient outcomes.

- What are some challenges of 3D printing in medicine? - Challenges include regulatory issues, material limitations, and the need for standardization in production processes.

- What does the future hold for 3D printing in healthcare? - The future may see advancements in bioprinting, improved materials, and greater integration of technology in medical applications.

Introduction to 3D Printing in Medicine

Imagine a world where medical solutions are tailored specifically to the unique anatomy of each patient. That world is not a distant dream anymore; it is unfolding right before our eyes, thanks to the revolutionary technology of 3D printing. This innovative approach is reshaping the medical field in ways we could only dream about a few years ago. From creating customized prosthetics to modeling organs for surgical planning, 3D printing is proving to be a game-changer in healthcare.

At its core, 3D printing, also known as additive manufacturing, involves creating three-dimensional objects layer by layer from a digital file. In medicine, this technology is being harnessed to produce intricate designs that cater to the specific needs of patients, enhancing both treatment outcomes and overall healthcare efficiency. For instance, instead of relying on one-size-fits-all solutions, doctors can now create prosthetics that fit perfectly, or even print out accurate models of a patient's organ for pre-surgical analysis.

One of the most exciting applications of 3D printing in medicine is in the realm of prosthetics. Traditionally, creating prosthetic limbs has been a time-consuming and expensive process. However, with 3D printing, the production time can be drastically reduced, and costs can be lowered significantly. Patients can receive prosthetics that not only fit better but also reflect their personal style, leading to improved comfort and satisfaction.

Moreover, the technology is making waves in surgical planning. Surgeons can now use 3D-printed models of a patient's anatomy to rehearse complex procedures. This hands-on practice allows for better preparation, reducing the risks associated with surgeries. Imagine a surgeon practicing on a replica of your heart or brain before performing an actual operation—this is the future of medicine!

As we delve deeper into the benefits of 3D printing, it becomes clear that this technology is not just a trend; it is a vital component of modern medicine that is set to grow exponentially. The possibilities are endless, and as research continues, we can expect to see even more innovative applications that will further enhance patient care and outcomes.

Benefits of 3D Printing in Healthcare

3D printing is not just a buzzword; it's a game changer in the healthcare sector. Imagine a world where medical devices are tailored specifically for each patient, where surgeries can be practiced on exact replicas of a patient's anatomy, and where the cost of producing complex medical devices is significantly reduced. This is the reality that 3D printing brings to the table. The benefits of this innovative technology are vast and varied, impacting everything from patient outcomes to cost efficiency.

One of the most remarkable advantages of 3D printing is its ability to create customized medical solutions. Unlike traditional manufacturing methods, which often involve a one-size-fits-all approach, 3D printing allows for the production of personalized prosthetics and implants. This means that devices can be designed to fit the unique anatomy of each patient, enhancing comfort and functionality. For instance, a patient needing a prosthetic limb can receive a device that is not only aesthetically pleasing but also designed specifically to their proportions and requirements. This level of customization can significantly improve the patient's quality of life, making them feel more confident and comfortable in their daily activities.

Moreover, 3D printing facilitates rapid prototyping. This means that medical professionals can quickly create and test new designs before moving to full-scale production. The speed at which new ideas can be transformed into tangible products is nothing short of revolutionary. For example, in surgical planning, surgeons can print out models of a patient's organs or even entire anatomical structures. This allows them to visualize complex cases and rehearse their surgical techniques, leading to better-prepared and more successful operations. The ability to iterate designs quickly also means that healthcare providers can respond to patient needs more effectively and efficiently.

Cost-effectiveness is another significant benefit of 3D printing in healthcare. Traditional manufacturing processes can be expensive and time-consuming, often involving multiple steps and extensive labor. In contrast, 3D printing can reduce these costs by streamlining the production process. For instance, a hospital can produce its own surgical tools and implants on-site, reducing the need for expensive inventory and long lead times. This not only saves money but also ensures that patients receive the most up-to-date and relevant medical devices. In fact, studies have shown that hospitals utilizing 3D printing technology can save upwards of 30-40% on certain medical devices.

In addition to these benefits, 3D printing opens the door to innovative treatments that were previously unimaginable. For example, researchers are exploring the potential of 3D printing to create bio-printed organs. While we are still in the early stages of this technology, the implications are staggering. Imagine a future where organ transplants are no longer reliant on donor availability but can be made on demand, tailored to the recipient's biological makeup. This could eliminate the waiting list for organ transplants and significantly reduce the risk of rejection.

To sum it up, the benefits of 3D printing in healthcare are profound and far-reaching. From customized prosthetics to cost savings and innovative treatments, this technology is paving the way for a new era in medicine. As we continue to explore the possibilities of 3D printing, it’s clear that the future of healthcare is not just about treating illnesses but about enhancing the overall patient experience.

- What is 3D printing in healthcare?

3D printing in healthcare refers to the use of additive manufacturing technologies to create medical devices, prosthetics, and even bioprinted tissues and organs tailored to individual patient needs. - How does 3D printing improve patient outcomes?

By allowing for customization of medical devices and enabling better surgical planning, 3D printing can lead to improved comfort, functionality, and overall patient satisfaction. - Is 3D printing cost-effective?

Yes, 3D printing can significantly reduce manufacturing costs by streamlining production processes and allowing for on-site creation of medical devices. - What are the future possibilities of 3D printing in medicine?

Future possibilities include the creation of bio-printed organs, advanced surgical simulations, and even personalized medications tailored to individual genetic profiles.

Customized Prosthetics and Implants

In the ever-evolving landscape of healthcare, stand out as a beacon of innovation, fundamentally altering the way patients experience recovery and rehabilitation. Imagine a world where every prosthetic limb or dental implant is crafted specifically for the individual, taking into account their unique anatomy and lifestyle. This is not just a futuristic dream; it's a reality made possible by 3D printing technology.

One of the most significant advantages of 3D printing in this arena is the ability to create tailored solutions that enhance both comfort and functionality. Traditional prosthetics often come in standard sizes and shapes, which can lead to discomfort, complications, and a lack of proper fit. However, with 3D printing, healthcare professionals can design and produce prosthetics that fit the patient's body like a glove. This level of customization not only improves the physical aspects of the prosthetic but also boosts the patient's confidence and quality of life.

For instance, consider a patient who has lost a limb due to an accident. Using advanced imaging techniques, doctors can create a precise model of the patient's residual limb. This model serves as the blueprint for crafting a custom prosthetic that aligns perfectly with the patient's body. The result? A prosthetic that allows for greater mobility, reduced pain, and a more natural range of motion. It's akin to tailoring a suit; when it fits perfectly, it enhances the overall experience.

Moreover, the implications extend beyond limb prosthetics. In the realm of dental care, 3D printing is revolutionizing the creation of dental implants and crowns. Traditional methods often involve multiple visits and uncomfortable fittings, but with 3D printing, a dentist can produce a precise dental implant in a fraction of the time. This not only streamlines the process but also significantly reduces the cost, benefiting both the patient and the healthcare system.

However, the journey of customization doesn't stop at just creating the perfect fit. As technology advances, we are witnessing the emergence of smart prosthetics that integrate sensors and AI, allowing for real-time adjustments based on the user's movements and activities. These innovations promise to take customization to an entirely new level, making prosthetics not just tools, but extensions of the human body.

In summary, the role of 3D printing in creating customized prosthetics and implants is a game-changer in the medical field. It empowers patients to regain their independence and enhances their overall quality of life. As we look to the future, the potential for even more personalized and advanced solutions seems limitless. The question remains: how far can we push the boundaries of 3D printing technology in healthcare? Only time will tell, but one thing is for sure—it's an exciting journey ahead!

Case Studies of Successful Implementations

When we talk about the impact of 3D printing in the medical field, it's not just theoretical; there are real-world examples that showcase its transformative power. Take, for instance, the case of a young boy named Owen, who was born with a rare condition that affected the development of his skull. Traditional surgical methods were risky and could lead to complications. However, a team of surgeons utilized 3D printing technology to create a customized skull implant that perfectly matched Owen's unique anatomy. The result? A successful surgery that not only improved his appearance but also his overall health and development.

Another remarkable example comes from the world of prosthetics. Jesse, a veteran who lost his leg in combat, benefited immensely from a 3D-printed prosthetic limb. Traditional prosthetics can be costly and uncomfortable, but Jesse's prosthetic was tailored specifically for him, enhancing both comfort and functionality. This personalized approach allowed Jesse to regain his mobility and independence, significantly improving his quality of life.

Furthermore, consider the advancements in surgical planning. Surgeons at a prominent hospital in California utilized 3D printing to create a replica of a patient’s heart for a complex surgery. By practicing on the 3D-printed model, the surgical team was able to anticipate challenges and refine their technique, leading to a smoother operation and quicker recovery for the patient. This case highlights how 3D printing not only aids in the creation of medical devices but also plays a crucial role in enhancing surgical outcomes.

These case studies underscore the potential of 3D printing to address unique medical challenges and improve patient care. The ability to create customized solutions tailored to individual needs is a game-changer in healthcare. As technology continues to evolve, we can expect to see even more innovative applications that will further enhance the patient experience and outcomes.

- What is 3D printing in healthcare? 3D printing in healthcare refers to the use of additive manufacturing technology to create medical devices, prosthetics, and models for surgical planning, tailored to individual patient needs.

- How does 3D printing improve patient outcomes? By enabling customization and rapid prototyping, 3D printing enhances the fit and functionality of medical devices, leading to better comfort and effectiveness in treatments.

- Are there any risks associated with 3D printing in medicine? Yes, there are regulatory and compliance challenges, as well as material limitations that need to be addressed to ensure safety and efficacy.

- What is the future of 3D printing in healthcare? The future looks promising, with ongoing research aimed at developing more biocompatible materials and expanding the range of applications within the medical field.

Future Trends in Customization

As we look towards the horizon of medical technology, the future trends in 3D printing customization are nothing short of exhilarating. Imagine a world where every patient receives treatment tailored specifically to their unique anatomy and health needs. This isn't just a dream—it's becoming a reality thanks to advances in 3D printing technology. The potential for customization in healthcare is expanding rapidly, and several key trends are emerging that promise to redefine the landscape of medical treatment.

One of the most exciting developments is the integration of bioprinting—a process that uses 3D printing techniques to create living tissues and organs. This technology holds the potential to produce customized organs for transplant, reducing the dependency on donor organs and minimizing rejection risks. Researchers are making strides in printing complex tissues that can mimic the structure and function of real organs, paving the way for a future where organ shortages could be a thing of the past.

Moreover, the rise of patient-specific models is revolutionizing surgical procedures. Surgeons can now create accurate replicas of a patient’s anatomy using their medical imaging data. This allows for detailed pre-surgical planning and practice on a model that mirrors the patient's unique body structure. As technology improves, we can expect these models to become even more intricate, incorporating real-time data to assist in decision-making during surgeries.

In addition, software advancements are playing a crucial role in enhancing customization. With the advent of artificial intelligence and machine learning, algorithms can analyze patient data and suggest optimal designs for implants and prosthetics. This means that the customization process will not only be faster but also more precise, leading to better patient outcomes. Imagine software that can predict how a prosthetic will fit based on the patient's lifestyle, activity level, and even their emotional response to the device!

Another trend to watch is the use of advanced materials. The development of new biocompatible materials will allow for even more customization in medical devices. For instance, researchers are working on materials that can change properties based on environmental stimuli, such as temperature or pH levels. This could lead to implants that adapt to the body's needs over time, providing a level of personalization that was previously unimaginable.

As we forge ahead, collaboration between medical professionals, engineers, and researchers will be essential. By working together, these groups can push the boundaries of what's possible in 3D printing, ensuring that the technology evolves in a way that meets the diverse needs of patients. The future of customization in healthcare is not just about technology; it's about creating a more patient-centered approach that considers the individual needs and experiences of each person.

In conclusion, the future trends in 3D printing customization in the medical field are poised to create a significant impact. From bioprinting to advanced materials and AI-driven design, the possibilities are endless. As these technologies continue to evolve, we can expect a healthcare landscape that is more responsive, efficient, and tailored to the needs of every patient.

- What is bioprinting? Bioprinting is a 3D printing technique that uses living cells to create tissues and organs.

- How does 3D printing improve surgical outcomes? By creating patient-specific models, surgeons can practice procedures beforehand, leading to more accurate and efficient surgeries.

- What materials are used in 3D printing for medical applications? A variety of materials are used, including biocompatible plastics, metals, and even living cells for bioprinting.

- Will 3D printing replace traditional manufacturing in healthcare? While it won't completely replace traditional methods, 3D printing offers significant advantages in customization and rapid prototyping.

Surgical Planning and Simulation

In the fast-evolving landscape of modern medicine, 3D printing has emerged as a game-changer, especially in the realm of . Imagine a surgeon preparing for a complex operation not just by studying scans and images, but by holding a tangible, accurate model of the patient's anatomy in their hands. This is where 3D printing steps in, transforming theoretical knowledge into practical application. By creating precise replicas of organs or structures, surgeons can plan their approach meticulously, reducing the risks associated with complex procedures.

The ability to print anatomical models allows for a deeper understanding of the surgical site. For instance, if a patient has a uniquely shaped tumor or an irregular heart structure, a 3D-printed model can be produced from their imaging data. This model becomes a crucial tool in preoperative discussions, enabling the surgical team to visualize the challenges they may face. It’s like having a practice run before the actual event, which can significantly enhance the surgical team's confidence and preparedness.

Moreover, the simulation aspect of 3D printing cannot be overstated. Surgeons can rehearse the operation on these models, experimenting with different techniques and approaches. This practice not only improves their skills but also helps in anticipating potential complications. The result? A more streamlined surgical process that minimizes the time spent in the operating room and maximizes patient safety. Just picture a pilot using a flight simulator to practice maneuvers before taking to the skies; it’s the same concept here, but with life-saving implications.

To illustrate the impact of 3D printing on surgical planning, consider the following table showcasing various applications and their benefits:

| Application | Benefits |

|---|---|

| Orthopedic Surgery | Custom bone models for fracture repair, improved surgical accuracy |

| Cardiac Surgery | Realistic heart models for complex valve repairs, enhanced procedural planning |

| Oncology | 3D tumor models for precise tumor resections, tailored treatment plans |

| Dental Surgery | Accurate dental implants and orthodontic models, improved patient outcomes |

As we look towards the future, the integration of augmented reality (AR) with 3D printing is on the horizon. Imagine surgeons wearing AR glasses that overlay digital information onto the physical world, allowing them to visualize critical data as they operate. This fusion of technologies could revolutionize surgical precision and patient outcomes even further.

In conclusion, the role of 3D printing in surgical planning and simulation is not just a trend; it's a significant leap forward in how we approach surgery. By providing surgeons with the tools they need to practice and plan effectively, we are paving the way for safer, more efficient surgical procedures that ultimately lead to better patient care. It’s like giving a chef the perfect recipe and all the right ingredients before they step into the kitchen—success is almost guaranteed.

Challenges Facing 3D Printing in Medicine

The adoption of 3D printing technology in the medical field has been nothing short of revolutionary. However, like any groundbreaking innovation, it comes with its own set of challenges that can hinder its widespread application. One of the primary obstacles is the regulatory landscape surrounding the use of 3D-printed medical devices. Regulatory bodies such as the FDA have stringent guidelines to ensure patient safety and product efficacy, which can slow down the approval process for new 3D-printed solutions. The need for standardization in production processes is crucial, as variations in manufacturing can lead to inconsistencies in product quality.

Another significant challenge is the material limitations associated with 3D printing. While there are several materials available for printing, not all are suitable for medical applications. For instance, biocompatibility is essential for any device that will be implanted in the body. Current materials may not always meet these requirements, leading to potential complications for patients. Researchers are actively exploring new materials that could enhance the functionality and safety of 3D-printed medical devices. Innovations in this area are critical, as they will pave the way for more advanced applications in the future.

Technical challenges also pose a barrier to the integration of 3D printing in healthcare. The technology requires specialized knowledge and training, which can be a hurdle for many medical professionals. Additionally, the complexity of creating intricate designs and ensuring precise measurements can lead to errors in production, resulting in devices that may not function as intended. As the technology evolves, there is a pressing need for comprehensive training programs that can equip healthcare professionals with the skills they need to utilize 3D printing effectively.

In summary, while the potential of 3D printing in medicine is immense, several challenges must be addressed to fully realize its benefits. From regulatory hurdles to material limitations and technical challenges, the path forward requires collaboration between innovators, regulatory bodies, and healthcare professionals. As we navigate these obstacles, the future of 3D printing in healthcare remains bright, promising advancements that could transform patient care.

- What are the main regulatory challenges for 3D printing in medicine? The main challenges include navigating FDA guidelines and ensuring standardization in production processes.

- What materials are currently used in 3D printing for medical applications? Commonly used materials include plastics, metals, and bio-compatible polymers, though research is ongoing to develop more advanced options.

- How can technical challenges be overcome in 3D printing? Providing specialized training and education for healthcare professionals can help address technical challenges and improve the quality of 3D-printed devices.

Regulatory and Compliance Issues

The integration of 3D printing technology into the medical field is not without its challenges, particularly when it comes to regulatory and compliance issues. As this revolutionary technology continues to evolve, the need for clear and effective regulations becomes increasingly important. The FDA (Food and Drug Administration) in the United States has set forth guidelines that govern the production and use of 3D-printed medical devices, but these regulations can often seem daunting and complex. One of the primary concerns is ensuring that these devices meet safety and efficacy standards before they reach patients.

For instance, the FDA categorizes 3D-printed medical devices into three classes based on the level of risk they pose. Class I devices are considered low risk and are subject to the least regulatory control, while Class III devices, which are high-risk, require premarket approval. This tiered approach aims to protect patients while also fostering innovation in the sector. However, the challenge lies in the fact that many 3D-printed products may not fit neatly into these categories, leading to confusion and potential delays in bringing life-saving technologies to market.

Moreover, the lack of standardization in the production processes of 3D-printed medical devices adds another layer of complexity. Each printer, material, and design can produce different outcomes, making it difficult to ensure consistency across batches. This inconsistency raises questions about the reliability and safety of these devices. Therefore, it is crucial for manufacturers to adhere to strict quality control measures and document their processes meticulously to comply with regulatory requirements.

In addition to safety and efficacy, manufacturers must also consider the implications of intellectual property (IP) rights. As 3D printing allows for the easy replication of designs, protecting innovative ideas becomes a significant issue. The legal landscape surrounding IP in the realm of 3D printing is still evolving, and companies must navigate these waters carefully to avoid potential infringement claims.

To summarize, the regulatory and compliance landscape for 3D printing in medicine is multifaceted and constantly changing. As technology advances, so too must the regulations that govern it. Stakeholders in the medical field, including manufacturers, healthcare providers, and regulatory bodies, must collaborate to establish a framework that not only ensures patient safety but also promotes innovation. The future of 3D printing in healthcare is bright, but it requires a concerted effort to overcome these regulatory hurdles.

- What are the main regulatory bodies overseeing 3D printing in healthcare? The FDA in the United States is the primary regulatory body, but other countries have their own agencies with similar responsibilities.

- How does the FDA classify 3D-printed medical devices? The FDA classifies them into three categories: Class I (low risk), Class II (moderate risk), and Class III (high risk), with varying levels of regulatory control.

- Why is standardization important in 3D printing for medical devices? Standardization ensures consistency, reliability, and safety across different batches of medical devices, which is crucial for patient safety.

- What are the challenges related to intellectual property in 3D printing? The ease of replicating designs raises concerns about IP rights, making it essential for companies to protect their innovations.

Material Limitations and Innovations

The realm of 3D printing in medicine is undeniably thrilling, yet it faces significant hurdles, particularly when it comes to the materials used in the process. While the technology has made remarkable strides, the limitations of current materials pose challenges that can impact the effectiveness and safety of 3D-printed medical devices. For instance, many materials used today lack the necessary biocompatibility, meaning they can cause adverse reactions when implanted in the human body. This is a critical concern for items such as prosthetics and implants, where patient safety is paramount.

Moreover, the durability of these materials often falls short. Many 3D-printed components may not withstand the rigors of daily use or the physiological conditions within the body. This could lead to premature failure of implants or prosthetics, ultimately impacting patient outcomes. To address these issues, researchers and innovators are tirelessly working to develop new materials that are not only biocompatible but also offer enhanced strength and longevity.

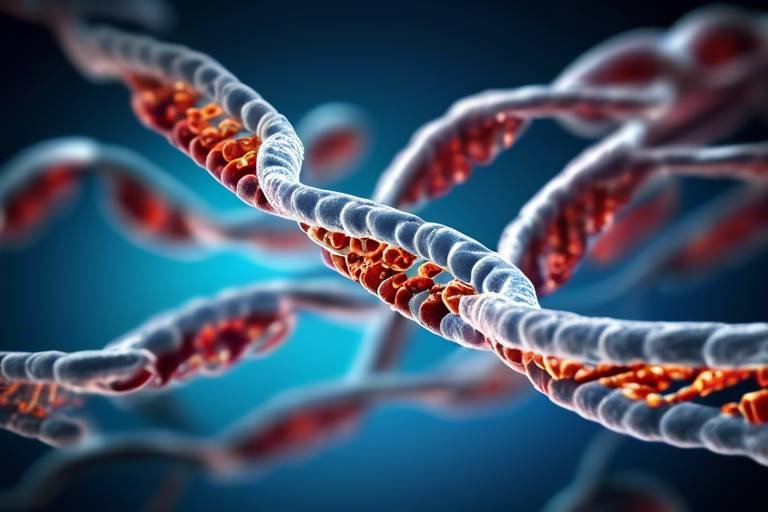

One area of innovation is the development of bioinks—materials that can be used in bioprinting to create living tissues. These bioinks are formulated from natural and synthetic polymers that can mimic the properties of human tissues, opening up exciting possibilities for regenerative medicine. For example, imagine being able to print a living organ that can seamlessly integrate with the body, reducing the need for organ transplants. Although this technology is still in its infancy, the potential is enormous.

Additionally, the introduction of smart materials is another exciting development. These materials can respond to environmental stimuli, such as temperature or pH changes, and could be used to create implants that adapt to the body’s needs over time. For instance, a smart implant could release medication in response to inflammation, providing targeted treatment and enhancing recovery.

| Material Type | Advantages | Limitations |

|---|---|---|

| PLA (Polylactic Acid) | Biodegradable, easy to print | Poor thermal stability, limited strength |

| PCL (Polycaprolactone) | Good biocompatibility, flexible | Slow degradation rate, lower strength |

| TPU (Thermoplastic Polyurethane) | High elasticity, durable | Not biodegradable, limited applications |

In conclusion, while the challenges surrounding 3D printing materials are significant, the ongoing research and innovations in this field are promising. As scientists and engineers continue to push the boundaries of material science, we can expect to see breakthroughs that not only enhance the safety and effectiveness of 3D-printed medical devices but also pave the way for new applications that we can only dream of today.

- What are bioinks? Bioinks are materials used in bioprinting that can create living tissues, made from natural and synthetic polymers.

- Why is material biocompatibility important? Biocompatibility ensures that materials do not cause adverse reactions when implanted in the body, which is crucial for patient safety.

- What are smart materials? Smart materials are materials that can respond to environmental changes, such as temperature or pH, and can be used in adaptive medical implants.

The Future of 3D Printing in Healthcare

The future of 3D printing in healthcare is not just a dream; it's an unfolding reality that promises to transform the landscape of medical treatment and patient care. Imagine walking into a hospital where your treatment plan is as unique as your DNA, where prosthetics are tailored to fit you perfectly, and where complex surgical procedures are rehearsed on exact replicas of your anatomy. This is the exciting horizon that 3D printing is paving the way for, and it’s happening faster than you might think.

As we look ahead, several key advancements are on the verge of making waves in the medical field:

- Bioprinting: One of the most promising areas is bioprinting, where living cells are used to create tissues and even organs. This could potentially eliminate the need for organ donors and reduce transplant rejection rates.

- Point-of-Care Printing: Imagine having a 3D printer in your doctor's office that can produce customized implants or models on the spot. This could drastically reduce waiting times and improve patient satisfaction.

- Enhanced Materials: Research is underway to develop more advanced materials that are not only biocompatible but also possess properties that can mimic the natural tissues of the body, making implants more effective.

Moreover, the integration of artificial intelligence with 3D printing technology is set to revolutionize the way we approach medical procedures. AI can analyze patient data and generate optimized models for surgical planning, ensuring that every operation is as precise as possible. This synergy could lead to a future where surgical errors are significantly reduced, and recovery times are shortened.

Another significant aspect of the future of 3D printing in healthcare is the potential for telemedicine. With the rise of remote healthcare services, 3D printing could allow patients in remote areas to receive customized care without having to travel long distances. For example, a patient could consult with a specialist virtually, and then have their custom prosthetic printed at a local facility, ensuring that they receive the care they need without the hassle of travel.

However, it's important to acknowledge that with great potential comes great responsibility. As the technology evolves, so too must the regulations surrounding it. Ensuring that 3D-printed medical devices meet safety and efficacy standards will be crucial in maintaining patient trust and health outcomes. The future will likely see a collaborative effort between healthcare providers, regulatory bodies, and technology developers to create a framework that supports innovation while safeguarding patient welfare.

In conclusion, the future of 3D printing in healthcare is bright and filled with possibilities. With advancements in bioprinting, point-of-care production, and AI integration, we are on the brink of a new era in medicine where personalized care becomes the norm rather than the exception. As we continue to explore these opportunities, the healthcare landscape will undoubtedly be reshaped, leading to improved patient outcomes and a more efficient medical system.

Q1: What is bioprinting?

A1: Bioprinting is a process that uses 3D printing technology to create living tissues and organs by layering cells. This technology holds the potential to revolutionize organ transplants and regenerative medicine.

Q2: How can 3D printing reduce surgery times?

A2: By allowing surgeons to practice procedures on accurate 3D models of a patient’s anatomy, they can familiarize themselves with the specific challenges of the operation, thus reducing the time spent in the operating room.

Q3: Are there any risks associated with 3D-printed medical devices?

A3: Yes, there are risks if the devices are not properly regulated. Ensuring that 3D-printed devices meet safety and efficacy standards is crucial to avoid complications in patient care.

Frequently Asked Questions

- What is 3D printing in the medical field?

3D printing in the medical field refers to the use of additive manufacturing technologies to create medical devices, prosthetics, implants, and even organ models. This innovative approach allows for the customization of products tailored to individual patient needs, significantly enhancing treatment outcomes.

- How does 3D printing improve patient outcomes?

By enabling the production of customized prosthetics and implants, 3D printing enhances comfort and functionality for patients. It also allows for rapid prototyping, which means that healthcare providers can quickly develop and test new devices, ultimately leading to better patient care and faster recovery times.

- What are some applications of 3D printing in healthcare?

3D printing has a wide range of applications in healthcare, including:

- Customized prosthetics and implants

- Organ and tissue modeling for surgical planning

- Creation of anatomical models for education and training

- Production of dental devices and orthodontics

- What challenges does 3D printing face in the medical field?

Despite its potential, 3D printing in medicine faces several challenges, such as:

- Regulatory and compliance issues, including the need for FDA approval

- Material limitations, as not all 3D printing materials are biocompatible

- Technical challenges related to the precision and reliability of printed devices

- How are regulatory issues addressed in 3D printing?

Regulatory agencies like the FDA are working to establish clear guidelines for the use of 3D printing in medicine. This includes creating standards for the manufacturing process and ensuring that products meet safety and efficacy requirements before they can be used in clinical settings.

- What is the future of 3D printing in healthcare?

The future of 3D printing in healthcare looks promising, with ongoing advancements in materials and technology. Innovations such as bioprinting, which involves printing living cells, could lead to the development of fully functional organs, revolutionizing organ transplantation and regenerative medicine.