Top AI Innovations Reshaping Industrial Processes

In today's fast-paced industrial landscape, artificial intelligence (AI) is not just a buzzword; it’s a game changer. Imagine a world where machines think, learn, and adapt to their environments, enhancing efficiency and productivity in ways we once only dreamed of. AI is reshaping industrial processes by integrating cutting-edge technologies that improve decision-making, streamline operations, and reduce costs. As we delve deeper into this transformative journey, we’ll uncover how AI innovations are revolutionizing various sectors, from manufacturing to supply chain management.

The impact of AI can be likened to the evolution of the steam engine; just as the steam engine revolutionized transportation and manufacturing in the 18th century, AI is now driving a similar wave of change. With the ability to analyze vast amounts of data, AI systems can provide insights that were previously unattainable, enabling industries to operate more effectively. For instance, consider the scenario of a manufacturing plant where AI algorithms can predict machinery failures before they occur. This proactive approach not only saves time but also significantly cuts down on maintenance costs.

As we explore the various AI innovations, it’s essential to highlight the key areas where these technologies are making the most significant impact:

- Automation and Robotics: AI-powered automation is streamlining manufacturing processes, allowing for precise and efficient operations.

- Predictive Maintenance: With AI, industries can anticipate equipment failures, reducing downtime and extending machinery lifespan.

- Data Analytics: Advanced analytics tools leverage AI to extract actionable insights from vast datasets.

- Energy Efficiency: AI innovations are optimizing energy consumption, helping industries lower operational costs.

In conclusion, the integration of AI into industrial processes is not just enhancing productivity but also paving the way for a more sustainable future. As we continue to explore the depths of AI technology, it becomes clear that the potential for innovation is limitless. The question remains: how will industries adapt to these changes, and what new frontiers will AI open up in the industrial sector?

Q: How is AI improving manufacturing processes?

A: AI enhances manufacturing by automating tasks, predicting maintenance needs, and providing data analytics that lead to more informed decision-making.

Q: What are the benefits of predictive maintenance?

A: Predictive maintenance allows industries to schedule repairs before equipment failures occur, minimizing downtime and extending the lifespan of machinery.

Q: How does AI contribute to energy efficiency?

A: AI analyzes energy usage patterns and optimizes consumption, helping companies reduce waste and lower operational costs.

Automation and Robotics

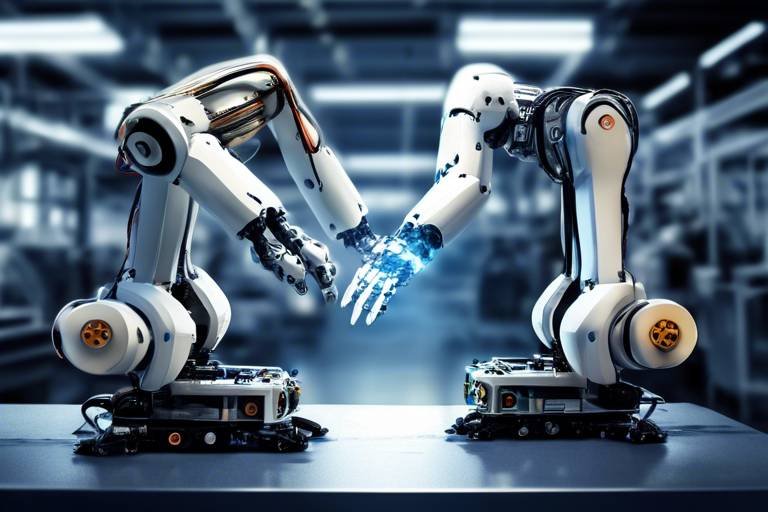

In the ever-evolving landscape of manufacturing, automation powered by artificial intelligence is not just a trend; it's a revolution. Imagine a factory floor where machines work seamlessly alongside humans, each enhancing the other's capabilities. This is the reality that AI-driven automation brings to the table. By integrating advanced robotics into industrial processes, companies are achieving unprecedented levels of efficiency and precision.

Robots equipped with AI can perform repetitive tasks with remarkable accuracy, significantly reducing the chances of human error. For instance, consider the assembly line of a car manufacturing plant. With AI-driven robots, tasks such as welding, painting, and assembly can be completed faster and with greater consistency than ever before. This not only leads to significant cost savings but also enhances the overall safety of the workplace. By taking over dangerous tasks, robots help in minimizing workplace accidents and injuries.

Moreover, the flexibility of modern robotics means that they can be easily programmed to handle a variety of tasks. This adaptability allows manufacturers to respond quickly to changes in production demands. For example, if a company needs to shift its focus from producing one type of product to another, AI-powered robots can be reconfigured in a matter of hours, rather than days. This leads to greater agility in production processes, enabling businesses to stay competitive in a fast-paced market.

To illustrate the impact of automation and robotics, let’s take a look at some key benefits:

- Increased Productivity: Automated systems can operate continuously without breaks, leading to higher output.

- Enhanced Quality: Robots maintain consistent quality standards, reducing defects and ensuring better product quality.

- Cost Efficiency: Reduced labor costs and minimized waste contribute to overall savings.

- Improved Safety: Robots can handle hazardous tasks, reducing the risk of injury for human workers.

As industries continue to embrace these technologies, the role of AI in automation will only grow stronger. Companies that invest in AI-driven robotics are not just enhancing their operational efficiency; they are also paving the way for a future where humans and machines collaborate harmoniously. This synergy not only boosts productivity but also fosters innovation, leading to new possibilities in product design and manufacturing processes.

In summary, the integration of automation and robotics powered by AI is transforming the industrial landscape. With their ability to enhance productivity, improve safety, and drive cost savings, these innovations are not just reshaping how products are made; they are redefining the future of work in industrial sectors.

Predictive Maintenance

In the fast-paced world of industrial operations, ensuring that machinery runs smoothly is crucial. That's where comes into play, transforming the way industries approach equipment upkeep. Instead of waiting for something to break down and then scrambling to fix it, companies can now leverage the power of artificial intelligence to anticipate potential failures before they happen. Imagine a crystal ball that tells you when your equipment is likely to fail—this is the essence of predictive maintenance.

By analyzing vast amounts of data collected from machines, predictive maintenance systems can identify patterns and trends that indicate when a piece of equipment might be on the verge of a breakdown. This proactive approach not only minimizes unexpected downtime but also extends the lifespan of machinery, allowing companies to get the most out of their investments. Picture a well-oiled machine that runs efficiently, thanks to timely interventions that prevent catastrophic failures.

To illustrate the impact of predictive maintenance, consider the following table that showcases key benefits and statistics associated with its implementation in industrial settings:

| Benefit | Statistic |

|---|---|

| Reduced Downtime | Up to 50% decrease in unplanned downtime |

| Cost Savings | 20-30% reduction in maintenance costs |

| Extended Equipment Lifespan | 15-25% increase in equipment lifespan |

| Improved Safety | Significant reduction in workplace accidents |

With predictive maintenance, organizations can schedule repairs during non-peak hours, ensuring that production schedules remain intact. This level of foresight is akin to having a personal trainer for your machines—constantly monitoring their health and pushing them to perform at their best. Furthermore, the data gathered can be used to refine maintenance strategies continuously, creating a feedback loop that enhances performance over time.

As industries embrace this innovative approach, they are not just improving their operational efficiency; they are also enhancing their competitiveness in a market that demands agility and reliability. The beauty of predictive maintenance lies in its ability to turn data into actionable insights, allowing companies to make informed decisions that drive success.

- What is predictive maintenance?

Predictive maintenance is a proactive maintenance strategy that uses data analysis and AI to predict when equipment failures might occur, allowing for timely repairs and minimizing downtime. - How does predictive maintenance work?

It works by collecting data from machinery sensors and using algorithms to identify patterns that indicate potential failures. - What are the benefits of predictive maintenance?

Benefits include reduced downtime, lower maintenance costs, extended equipment lifespan, and improved safety. - Is predictive maintenance expensive to implement?

While there may be initial costs, the long-term savings and efficiency gains often outweigh the investment.

Data Analytics in Manufacturing

In the fast-paced world of manufacturing, data analytics has emerged as a game-changer. Imagine having the ability to sift through mountains of data and extract valuable insights that can significantly enhance production efficiency. This is precisely what advanced data analytics tools powered by artificial intelligence are doing for manufacturers today. By leveraging complex algorithms and machine learning techniques, these tools can analyze vast datasets in real-time, uncovering trends and patterns that were previously hidden from view.

Consider this: every machine, sensor, and employee generates data. When properly harnessed, this data can be transformed into actionable insights. For instance, by analyzing operational data, manufacturers can identify bottlenecks in their production lines, leading to informed decisions that streamline processes and enhance productivity. The result? A more agile manufacturing environment that can adapt quickly to changing market demands.

One of the standout features of AI-driven data analytics is its ability to predict potential issues before they escalate. This predictive capability allows manufacturers to implement preventive measures, mitigating risks and reducing downtime. For example, if a machine shows signs of wear and tear, data analytics can alert managers to schedule maintenance before a breakdown occurs, saving both time and money.

Moreover, data analytics plays a critical role in optimizing resource allocation. By analyzing historical data, manufacturers can forecast demand more accurately, ensuring that they have the right amount of inventory on hand. This not only reduces waste but also enhances customer satisfaction by improving delivery times. To illustrate this point, consider the following table that highlights the impact of data analytics on key manufacturing metrics:

| Metric | Before Data Analytics | After Data Analytics |

|---|---|---|

| Production Efficiency | 70% | 90% |

| Downtime | 15% | 5% |

| Inventory Costs | $200,000 | $120,000 |

As we can see, the implementation of data analytics has led to remarkable improvements across various metrics. The journey to becoming a data-driven manufacturer is not without its challenges, but the rewards far outweigh the risks. By embracing these advanced analytics tools, manufacturers can not only boost their operational efficiency but also foster a culture of continuous improvement.

In summary, the integration of data analytics in manufacturing is not just a trend; it’s a necessity for companies aiming to stay competitive in today's market. With the ability to analyze data in real-time, predict outcomes, and optimize processes, manufacturers are better equipped to meet the demands of a rapidly evolving industry.

- What is data analytics in manufacturing? Data analytics in manufacturing refers to the process of analyzing data generated by manufacturing operations to gain insights that can improve efficiency, reduce costs, and enhance decision-making.

- How does AI improve data analytics? AI enhances data analytics by enabling real-time data processing, predictive analysis, and the ability to identify complex patterns that traditional methods may overlook.

- What are the benefits of using data analytics in manufacturing? Benefits include increased production efficiency, reduced downtime, optimized resource allocation, and improved quality control.

- Can small manufacturers benefit from data analytics? Absolutely! Data analytics can provide valuable insights for manufacturers of all sizes, helping them to streamline operations and compete effectively.

Real-time Monitoring

In today's fast-paced industrial landscape, has emerged as a game-changer, enabling manufacturers to maintain a competitive edge. Imagine being able to watch over your production line as if you were standing right there on the factory floor—this is the power that AI brings to the table. With advanced sensors and machine learning algorithms, industries can now receive instant feedback on their operations, allowing them to make quick adjustments and decisions. This capability not only ensures that products meet quality standards but also minimizes disruptions that can lead to costly downtime.

Real-time monitoring systems collect data from various sources, including machinery, sensors, and even environmental conditions. The beauty of these systems lies in their ability to analyze this data on-the-fly. For instance, if a machine starts to operate outside its normal parameters, the system can immediately alert operators, who can then take corrective action before a minor issue escalates into a major problem. This proactive approach to manufacturing is akin to having a vigilant guardian watching over your operations, ensuring everything runs smoothly.

Moreover, the integration of AI-driven dashboards allows managers to visualize data trends and performance metrics at a glance. These dashboards can display key performance indicators (KPIs), such as production rates, machine efficiency, and even energy consumption. By leveraging this information, companies can identify bottlenecks and inefficiencies in real-time, leading to better resource allocation and improved productivity.

In addition to enhancing operational efficiency, real-time monitoring fosters a culture of continuous improvement. When employees can see how their work directly impacts production outcomes, they are more likely to engage in problem-solving and innovation. This dynamic creates a feedback loop where data-driven insights lead to actionable changes, ultimately resulting in a more agile and responsive manufacturing environment.

To illustrate the impact of real-time monitoring, consider the following table that outlines the benefits and features of implementing such systems in industrial settings:

| Feature | Benefit |

|---|---|

| Instant Alerts | Immediate notification of anomalies, reducing response time. |

| Data Visualization | Clear insights into production metrics for informed decision-making. |

| Predictive Analytics | Anticipate potential issues before they arise, minimizing downtime. |

| Employee Engagement | Empowers workers to take ownership of their processes, fostering innovation. |

In summary, real-time monitoring powered by AI is not just a trend; it's a necessity in modern manufacturing. By harnessing the capabilities of AI, industries can transform their operations, making them more efficient, responsive, and ultimately more profitable. As we continue to embrace these technologies, the future of industrial processes looks brighter than ever.

- What is real-time monitoring in industrial processes? Real-time monitoring involves the continuous tracking of production processes using AI and sensor technologies to ensure optimal performance and quality.

- How does AI improve real-time monitoring? AI enhances real-time monitoring by analyzing data quickly, providing instant feedback, and predicting potential issues before they escalate.

- What are the benefits of implementing real-time monitoring? Benefits include increased operational efficiency, reduced downtime, improved product quality, and enhanced employee engagement.

- Can real-time monitoring systems be integrated with existing machinery? Yes, many real-time monitoring systems are designed to be compatible with a wide range of industrial equipment, making integration seamless.

Quality Control Automation

In the fast-paced world of manufacturing, has emerged as a game-changer, transforming the way industries ensure product excellence. Imagine a scenario where every product that rolls off the assembly line is inspected with the precision of a hawk's eye, detecting even the tiniest defects that a human inspector might miss. This is the power of AI-driven automation in quality control.

At the heart of this innovation lies computer vision technology, which employs advanced algorithms and machine learning to analyze visual data. These systems are trained to recognize patterns and anomalies, allowing them to flag defects in real-time. For instance, if a product has a scratch, dent, or any other imperfection, the AI can instantly identify it, ensuring that only flawless items reach the consumer. This not only enhances product quality but also significantly reduces the costs associated with manual inspections.

Furthermore, the integration of AI in quality control processes leads to a more consistent and reliable output. Traditional methods often involve human judgment, which can be subjective and prone to errors. By automating this process, manufacturers can achieve a level of precision that is simply unattainable through human effort alone. In fact, studies have shown that AI systems can detect defects with an accuracy rate exceeding 95%, compared to human inspectors who typically hover around 80%.

But how does this all work in practice? Let’s break it down:

- Data Collection: High-resolution cameras capture images of products as they move along the production line.

- Image Processing: AI algorithms analyze these images, comparing them against pre-defined quality standards.

- Real-time Feedback: If a defect is detected, the system can automatically reject the product or alert operators for further inspection.

- Continuous Learning: The AI system continually learns from new data, improving its accuracy and efficiency over time.

Moreover, the benefits of quality control automation extend beyond just defect detection. By implementing these systems, companies can gather valuable data on production trends and quality metrics. This data can be analyzed to identify recurring issues, leading to improvements in the manufacturing process itself. In essence, quality control automation not only serves as a safeguard for product quality but also acts as a catalyst for continuous improvement within manufacturing operations.

As industries strive for greater efficiency and competitiveness, the adoption of AI-driven quality control automation is becoming increasingly vital. It represents a shift from reactive to proactive quality management, where potential issues are identified and rectified before they escalate into larger problems. This not only enhances customer satisfaction by ensuring high-quality products but also strengthens the overall brand reputation in a competitive marketplace.

In conclusion, quality control automation powered by AI is not just a technological advancement; it’s a revolution in how industries approach product quality. By embracing this innovation, manufacturers can achieve unprecedented levels of accuracy, efficiency, and reliability, paving the way for a future where quality is guaranteed from the very first step of the production process.

- What is quality control automation? Quality control automation refers to the use of AI and computer vision technologies to inspect products for defects and ensure they meet quality standards without human intervention.

- How does AI improve quality control? AI enhances quality control by providing consistent, accurate inspections that reduce human error, allowing for real-time feedback and continuous improvement in manufacturing processes.

- Can quality control automation save costs? Yes, by reducing the need for manual inspections and minimizing defects, companies can save on labor costs and reduce waste, leading to overall cost savings.

Supply Chain Optimization

In today's fast-paced industrial landscape, has become a critical factor for success. With the advent of artificial intelligence, companies are now equipped with tools that allow them to not only streamline their operations but also to anticipate market changes with remarkable precision. Imagine being able to predict demand fluctuations before they happen! This capability is no longer a distant dream; it’s a reality that AI brings to the table.

AI technologies analyze vast amounts of data from various sources, including sales trends, market conditions, and even weather patterns, to create accurate forecasts. This means that organizations can adjust their inventory levels proactively, ensuring they have the right products at the right time. For instance, if a particular item is expected to see a surge in demand due to an upcoming holiday, AI can signal the need for increased production and stock levels, thus preventing shortages and lost sales.

Furthermore, AI enhances supply chain efficiency by optimizing logistics and distribution. By utilizing algorithms that consider multiple variables—such as transportation costs, delivery times, and route efficiency—companies can make smarter decisions about how to get their products to market. This not only reduces operational costs but also improves customer satisfaction. After all, who doesn’t love a prompt delivery?

Another exciting aspect of AI in supply chain optimization is its ability to foster collaboration among different stakeholders. With AI-driven platforms, suppliers, manufacturers, and retailers can share real-time data, leading to better communication and coordination. This interconnectedness ensures that everyone is on the same page, ultimately resulting in a more resilient supply chain.

To illustrate the impact of AI on supply chain optimization, consider the following table:

| AI Application | Benefit |

|---|---|

| Demand Forecasting | Reduces excess inventory and stockouts |

| Logistics Optimization | Lowers transportation costs and improves delivery times |

| Supplier Collaboration | Enhances communication and coordination |

| Risk Management | Identifies potential disruptions and mitigates them |

In summary, the integration of AI into supply chain management is not just a trend; it’s a revolution that is reshaping how industries operate. By leveraging these advanced technologies, businesses can not only enhance their efficiency and reduce costs but also create a more agile and responsive supply chain that meets the ever-evolving demands of the market.

- What is supply chain optimization? Supply chain optimization refers to the process of improving the efficiency and effectiveness of a supply chain to reduce costs and improve service delivery.

- How does AI help in supply chain optimization? AI helps by analyzing data to forecast demand, optimizing logistics, and enhancing collaboration among stakeholders, leading to improved decision-making.

- What are the benefits of using AI in supply chain management? Benefits include reduced operational costs, improved customer satisfaction, better risk management, and enhanced overall efficiency.

- Can small businesses benefit from AI in supply chain optimization? Absolutely! Small businesses can leverage AI tools to compete effectively by optimizing their operations and making data-driven decisions.

Energy Efficiency

In today's fast-paced industrial landscape, has become more than just a buzzword; it's a necessity. As companies strive to reduce their operational costs and minimize their environmental impact, artificial intelligence is stepping in as a game-changer. By leveraging cutting-edge technologies, industries can now optimize their energy consumption in ways that were previously unimaginable.

Imagine a factory where machines communicate with each other and adjust their energy usage based on real-time data. This is the power of AI-driven innovations that analyze usage patterns and make instant decisions to enhance efficiency. For instance, smart algorithms can identify peak energy usage times and suggest adjustments, ensuring that energy is consumed only when necessary. This not only reduces costs but also contributes to a greener planet.

One of the standout features of AI in energy efficiency is its ability to integrate with existing systems seamlessly. Industries can implement AI solutions without overhauling their entire infrastructure, making it a cost-effective approach. Moreover, the data collected from AI systems can be used to create comprehensive reports that highlight energy consumption trends, allowing companies to make informed decisions about future investments in energy-saving technologies.

To illustrate the impact of AI on energy efficiency, consider the following table that outlines key benefits:

| Benefit | Description |

|---|---|

| Cost Reduction | Minimizing energy waste leads to significant savings on utility bills. |

| Improved Reliability | AI systems can predict equipment failures, reducing downtime and maintenance costs. |

| Sustainability | Optimizing energy use helps industries meet their sustainability goals. |

| Enhanced Productivity | With efficient energy use, machines can operate at their best, boosting overall productivity. |

Furthermore, AI-driven technologies are revolutionizing the way industries approach smart grid technologies. These innovations not only enhance energy distribution but also improve management practices. By utilizing AI, companies can predict energy demand and adjust their supply accordingly, ensuring that resources are used efficiently. This proactive approach not only saves money but also strengthens the reliability of energy sources.

As industries continue to adopt AI solutions, a notable trend has emerged: the focus on carbon footprint reduction. By optimizing processes and energy consumption, companies can effectively monitor their environmental impact. AI tools can analyze emissions data and suggest actionable strategies to minimize carbon footprints, aligning business operations with sustainability objectives.

In conclusion, the integration of AI in energy efficiency is not just a technological advancement; it's a transformative shift that benefits both industries and the environment. By embracing these innovations, companies can pave the way for a more sustainable future while reaping the rewards of cost savings and enhanced productivity.

- What is energy efficiency in industrial processes? Energy efficiency refers to the use of technology and practices that reduce the amount of energy required to provide the same level of output or service.

- How does AI contribute to energy efficiency? AI analyzes data patterns to optimize energy usage, predict demand, and enhance overall operational efficiency.

- What are smart grid technologies? Smart grid technologies use AI to improve energy distribution and management, allowing for better reliability and cost-effectiveness.

- Can AI help in reducing carbon footprints? Yes, AI can monitor and optimize processes, leading to a reduction in energy consumption and, consequently, a smaller carbon footprint.

Smart Grid Technologies

In today's rapidly evolving industrial landscape, are becoming a cornerstone for enhancing energy distribution and management. Imagine a world where energy flows seamlessly, where every kilowatt is monitored, managed, and utilized to its fullest potential. This is the promise of smart grids, powered by cutting-edge AI innovations that optimize how industries consume and distribute energy.

At the heart of smart grid technologies lies the ability to collect and analyze vast amounts of data in real time. This capability enables industries to respond swiftly to fluctuations in energy demand and supply. For example, during peak hours, AI algorithms can automatically adjust energy distribution, ensuring that resources are allocated efficiently and preventing outages. This not only enhances reliability but also significantly reduces operational costs.

Moreover, smart grids facilitate the integration of renewable energy sources such as solar and wind into the energy mix. Traditional grids often struggle to accommodate the intermittent nature of these energy sources, but AI-driven smart grids can predict energy generation patterns and adjust consumption accordingly. This flexibility not only promotes sustainability but also helps industries meet their carbon reduction targets.

Another exciting aspect of smart grid technologies is their ability to empower consumers. With real-time data at their fingertips, businesses can make informed decisions about energy use, leading to cost savings and increased efficiency. For instance, companies can shift their energy-intensive processes to off-peak hours when electricity is cheaper, maximizing their operational budgets.

To illustrate the impact of smart grid technologies, consider the following table that showcases key benefits:

| Benefit | Description |

|---|---|

| Enhanced Reliability | Minimizes outages and ensures consistent energy supply through real-time monitoring. |

| Cost Reduction | Optimizes energy distribution, leading to lower operational costs for industries. |

| Sustainability | Facilitates the integration of renewable energy sources, reducing carbon emissions. |

| Consumer Empowerment | Provides real-time data, enabling businesses to make informed energy decisions. |

In conclusion, the implementation of smart grid technologies is not just a trend; it’s a necessary evolution in the industrial sector. By leveraging AI, industries can transform their energy management practices, paving the way for a more efficient, sustainable, and economically viable future. As we continue to innovate and adapt, the potential of smart grids will only expand, making them an indispensable part of our industrial ecosystem.

- What are smart grid technologies?

Smart grid technologies refer to advanced systems that use digital communications to detect and react to local changes in usage, improving the reliability and efficiency of electricity distribution. - How do smart grids contribute to energy efficiency?

Smart grids optimize energy consumption through real-time monitoring and data analysis, allowing for better management of energy resources and reducing waste. - Can smart grids integrate renewable energy sources?

Yes, smart grids are designed to accommodate renewable energy sources, improving their stability and reliability in the energy mix. - What are the benefits of using smart grid technologies in industries?

Benefits include enhanced reliability, cost reduction, sustainability through renewable energy integration, and empowering consumers with real-time data.

Carbon Footprint Reduction

In today's world, where environmental concerns are at the forefront, reducing carbon footprints has become a crucial goal for industries across the globe. Artificial Intelligence (AI) is stepping up to the plate, offering innovative solutions that not only help companies maintain productivity but also work towards a more sustainable future. Imagine a scenario where businesses can operate efficiently while simultaneously minimizing their impact on the planet. That's the magic of AI!

AI technologies enable industries to monitor and analyze their energy consumption patterns, identifying areas where they can cut down on waste. By utilizing advanced algorithms, organizations can optimize their processes, leading to significant reductions in greenhouse gas emissions. For instance, AI can predict energy needs based on historical data, allowing companies to adjust their consumption accordingly. This is akin to having a personal coach who guides you on how to save energy while maintaining peak performance.

Moreover, AI-driven solutions can automate the management of resources, ensuring that every ounce of energy is used wisely. By implementing AI systems, companies can achieve a more efficient allocation of resources, which not only saves money but also contributes to sustainability efforts. Consider the following benefits:

- Enhanced Monitoring: AI tools provide real-time data on energy usage, allowing industries to make informed decisions quickly.

- Predictive Analytics: By forecasting energy needs, AI helps prevent overconsumption and waste.

- Process Optimization: AI can streamline operations to ensure that energy is used in the most efficient manner possible.

To put things into perspective, let's take a look at a hypothetical scenario where a manufacturing company implements AI solutions. Before AI, they might have been using outdated machinery that consumed excessive energy. With AI, they can upgrade to smart machines that adapt their energy usage based on real-time demand, ultimately reducing their carbon emissions significantly. This transformation not only benefits the environment but also enhances the company's bottom line.

Furthermore, AI can assist in compliance with environmental regulations. As governments worldwide tighten regulations on emissions, companies using AI can easily track their carbon footprint and make necessary adjustments to stay compliant. This proactive approach not only avoids potential fines but also showcases a commitment to sustainability, which is increasingly important to consumers.

In summary, the integration of AI in industrial processes offers a pathway to substantial carbon footprint reductions. As industries continue to embrace these technologies, we can expect to see a significant shift towards more sustainable practices. The future is bright for businesses willing to innovate and invest in AI solutions that prioritize both profitability and environmental responsibility.

Q1: How does AI help in reducing carbon footprints?

AI helps by optimizing energy consumption, automating resource management, and providing real-time monitoring of energy usage, which leads to significant reductions in greenhouse gas emissions.

Q2: Can small businesses benefit from AI in terms of sustainability?

Absolutely! Small businesses can use AI tools to analyze their energy consumption patterns and implement cost-effective solutions that reduce waste and improve efficiency.

Q3: Are there specific AI technologies that focus on energy efficiency?

Yes, technologies like smart grids, predictive analytics, and machine learning algorithms are specifically designed to enhance energy efficiency and reduce carbon footprints in various industries.

Frequently Asked Questions

- What is the role of AI in automation and robotics?

AI plays a pivotal role in automation and robotics by enhancing the precision and efficiency of manufacturing processes. With AI, robots can perform tasks with minimal human intervention, significantly reducing the chances of errors and improving safety in industrial settings.

- How does predictive maintenance work?

Predictive maintenance uses AI algorithms to analyze data from machinery and equipment. By identifying patterns and potential issues before they cause failures, industries can schedule maintenance proactively, thereby minimizing downtime and extending the life of their assets.

- What benefits do advanced data analytics offer in manufacturing?

Advanced data analytics powered by AI allows manufacturers to extract valuable insights from large datasets. This leads to optimized production processes, reduced waste, and enhanced operational efficiency, ultimately boosting productivity and profitability.

- How does AI facilitate real-time monitoring in production?

AI enables real-time monitoring by providing instant feedback and alerts on production lines. This capability allows manufacturers to make immediate adjustments, ensuring consistent product quality and minimizing disruptions in workflows.

- Can AI improve quality control processes?

Absolutely! AI can automate quality control using computer vision and machine learning techniques to detect defects in products. This not only improves product quality but also reduces inspection costs, making the entire process more efficient.

- How does AI enhance supply chain management?

AI enhances supply chain management by predicting demand fluctuations and optimizing inventory levels. This results in reduced costs, improved delivery times, and better alignment with customer needs, ultimately leading to increased customer satisfaction.

- What impact does AI have on energy efficiency?

AI innovations help industries optimize their energy consumption by analyzing usage patterns. This leads to reduced waste and lower operational costs, making businesses more sustainable and cost-effective.

- What are smart grid technologies?

Smart grid technologies driven by AI improve energy distribution and management. These innovations enhance reliability, reduce costs, and facilitate the integration of renewable energy sources, contributing to a more sustainable energy landscape.

- How can AI help in reducing carbon footprints?

AI solutions assist industries in monitoring and reducing their carbon footprints by optimizing processes and energy usage. This helps companies achieve their sustainability goals while maintaining productivity and profitability.